Smooth process development in friction stir welding

The process

For us, process development for each customer application and the provision of adapted friction tools are part of our holistic approach to friction stir welding.

The welding system, process parameters and welding tool are always optimally matched to each other: This results in the best possible joint quality. We work closely with our customers to develop the joining concept.

- As early as the component design phase, we provide support in designing the assembly to match the friction stir welding process.

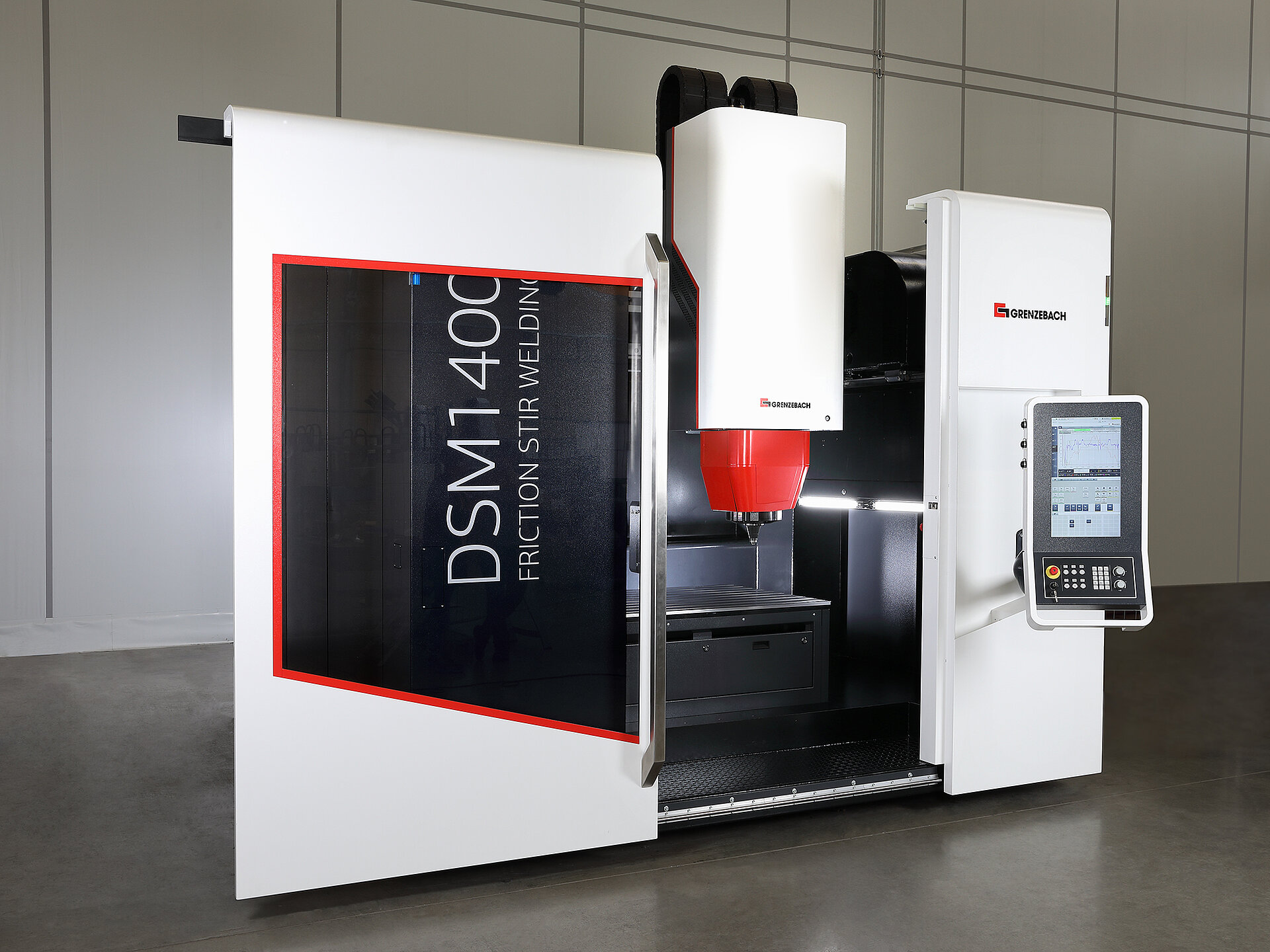

- Test, sample and prototype welding as well as contract manufacturing orders are possible on Grenzebach’s in-house FSW equipment.

Tool technology for high-quality friction

To ensure successful FSW, tool technology is as important as system technology.

It is very important to us to provide you with the right tools: our wear-resistant and robust FSW tools are developed in-house by Grenzebach experts and customized for your requirements.

The holistic Grenzebach solution leaves nothing to chance. There are two options for FSW friction tools: one-piece (conventional) and two-piece tools (DynaSTIR). Our portfolio contains both!

One-piece welding tool with rotating shoulder

MonoSTIR friction stir welding technology

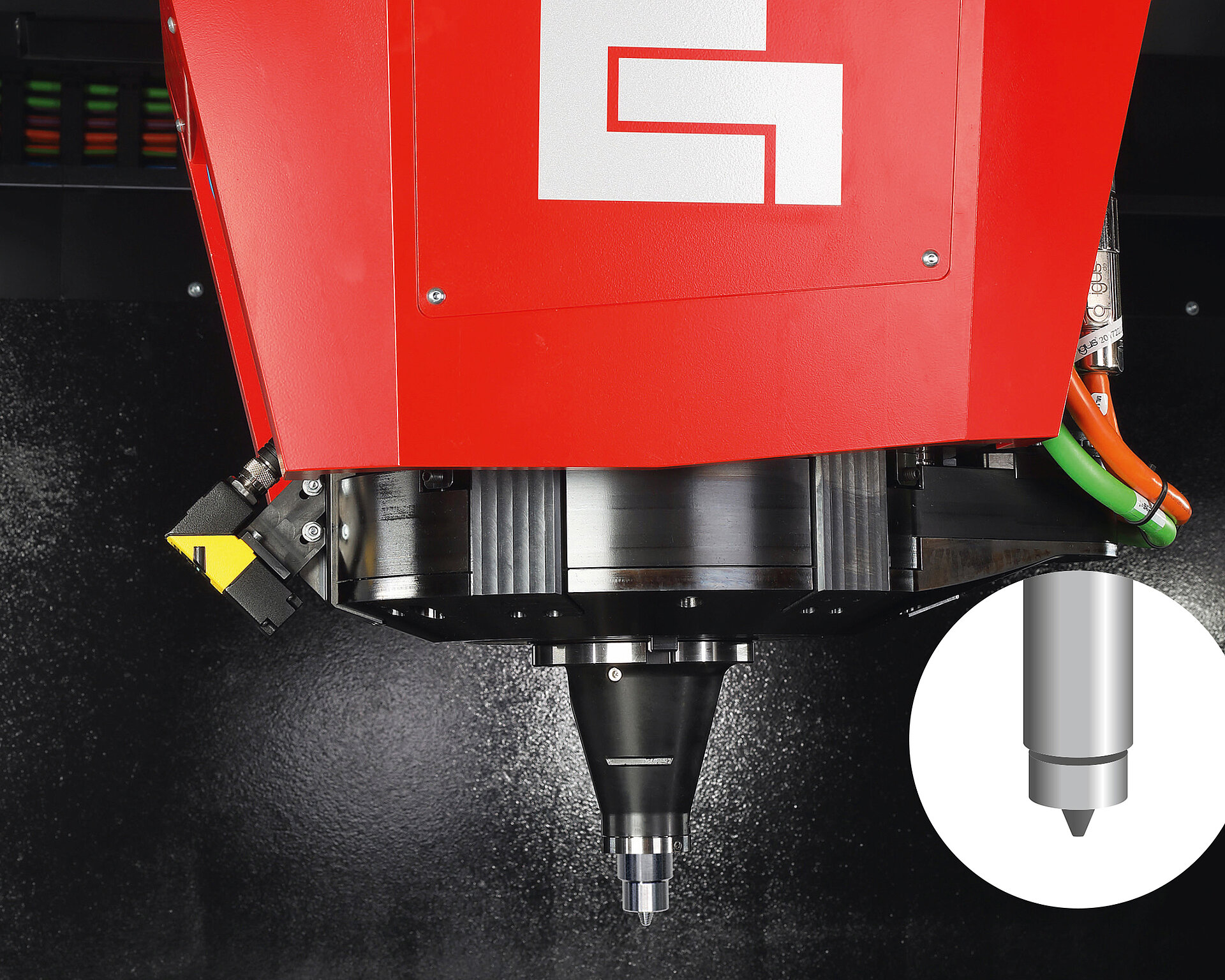

Two-piece tool with rotating friction pin and non-rotating shoulder

DynaSTIR friction stir welding technology

In brief: MonoSTIR tool technology for friction stir welding

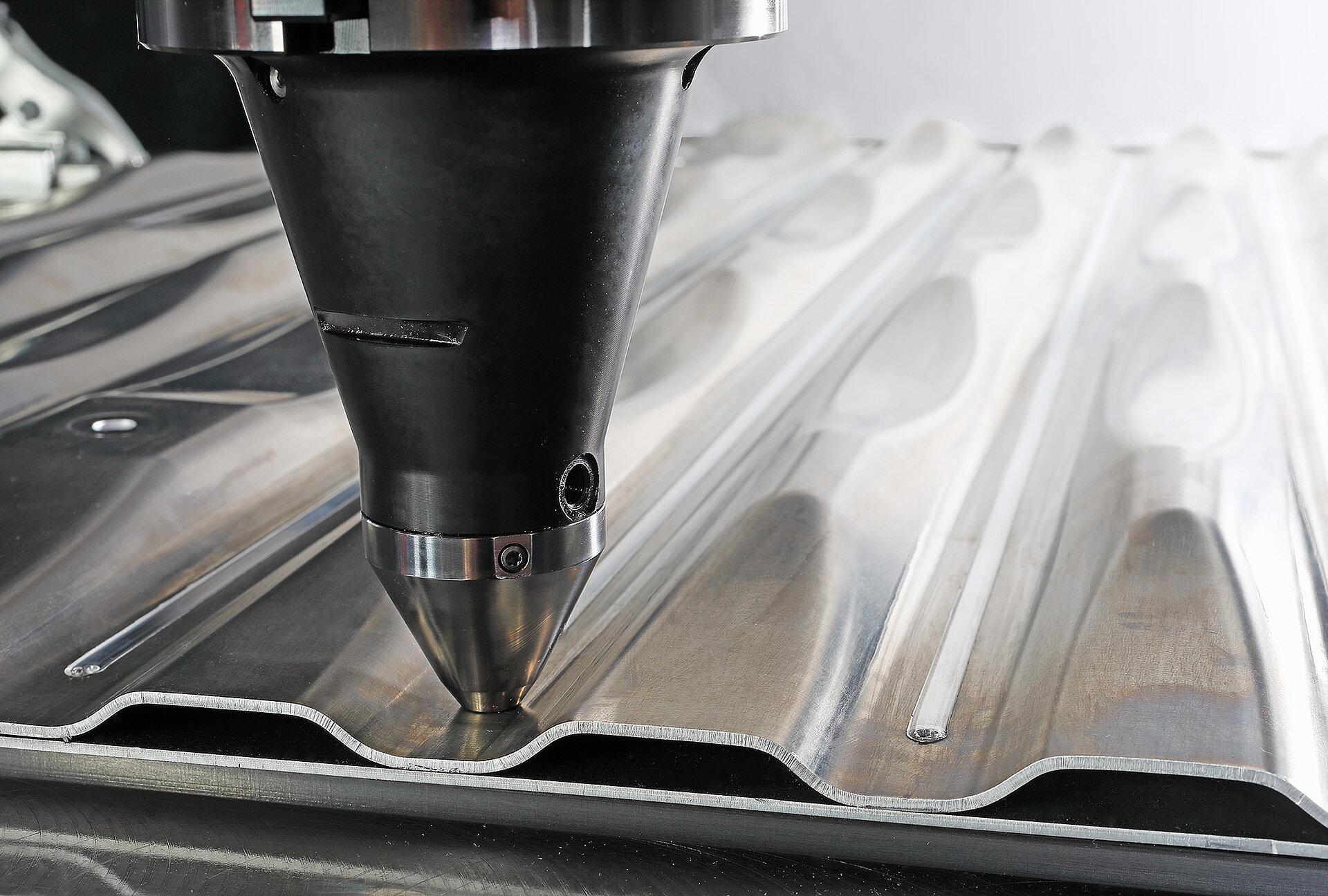

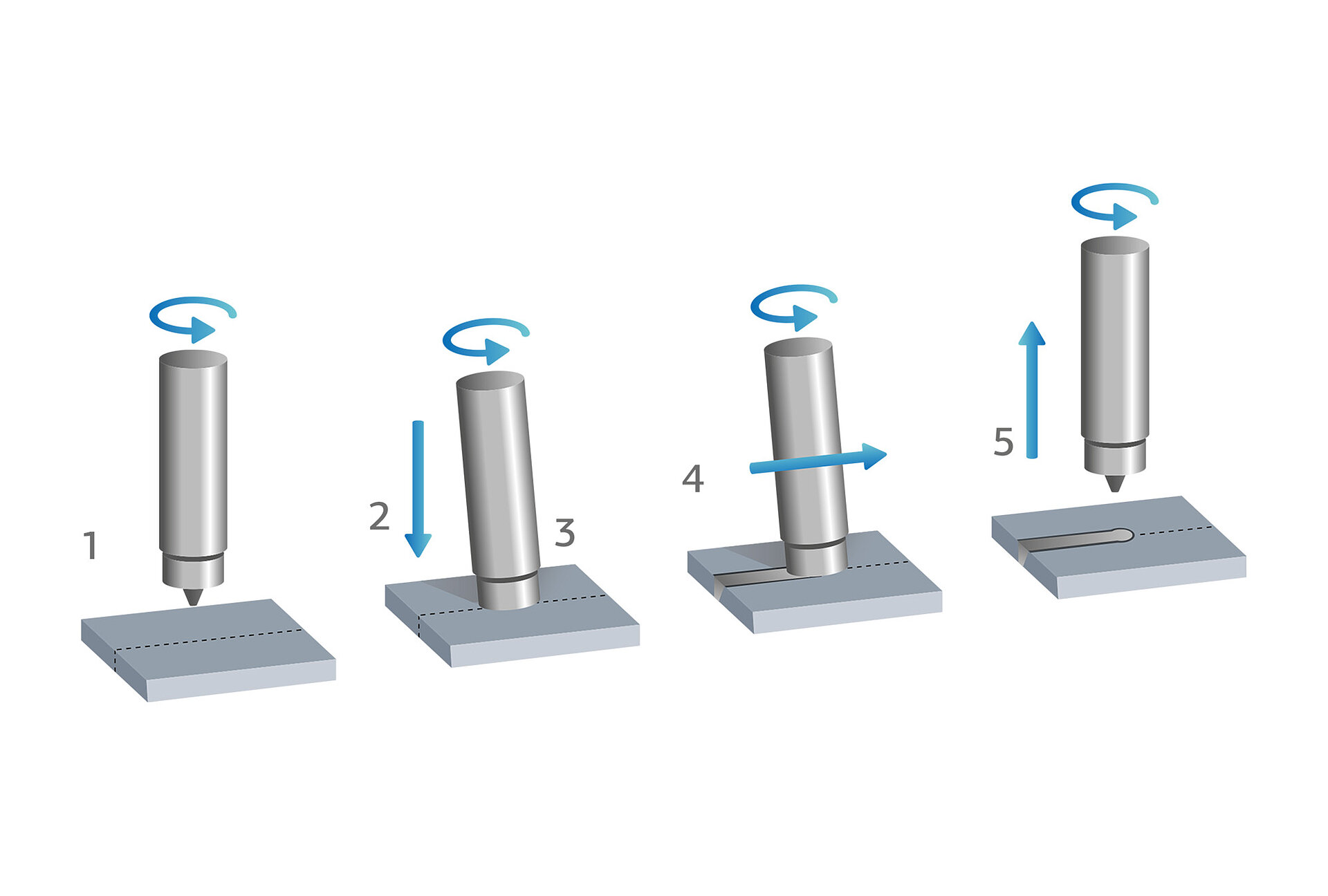

The process at a glance: the rotating wear-resistant welding tool (1) dips into the seam (2. immersion process) and generates frictional heat. The material becomes plastically deformable and is stirred by the forward movement of the tool along the seam (3. feed). The tool is removed from the seam. The result is a firm, media- and pressure-tight joint between the workpieces (4. removal).

- One-piece welding tool with rotating shoulder

- Ideal for high welding speeds and depths

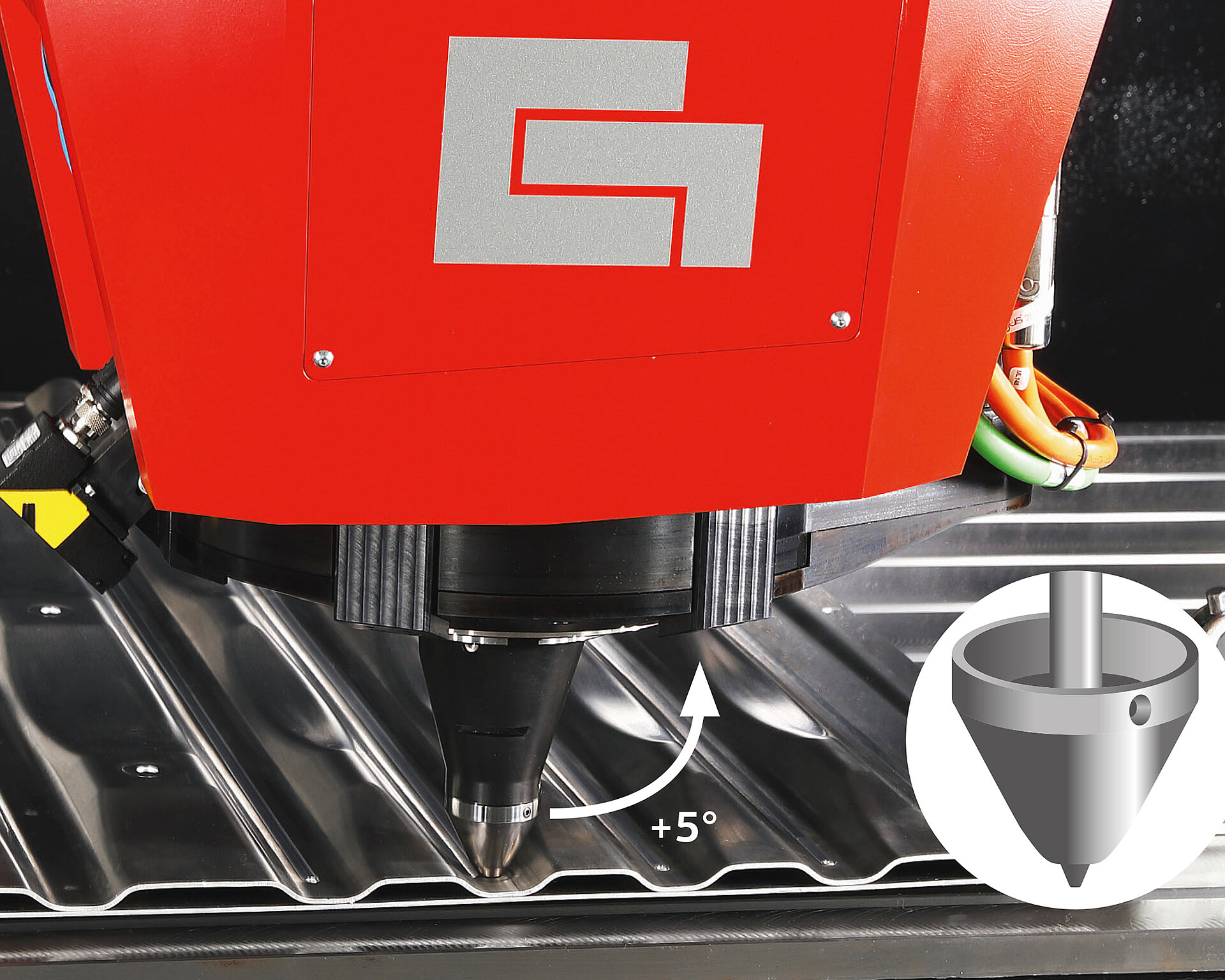

- Force-controlled process with high-precision sensor technology in the welding head

- Integrated 0 - 5° swivel axis

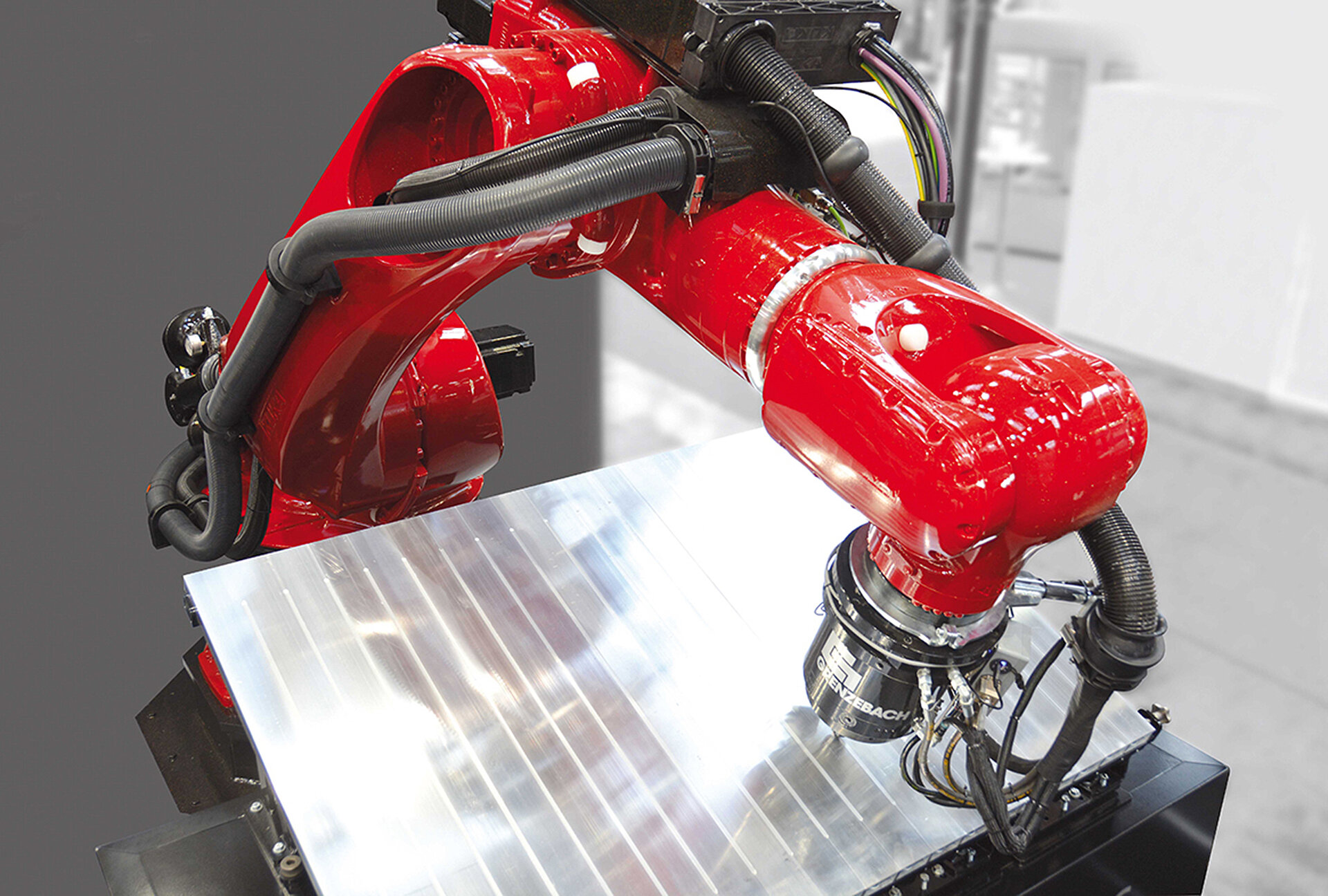

DynaSTIR: dynamic tool technology for friction stir welding

We asked ourselves how a good process could be further improved. With DynaSTIR tool technology, we found an answer.

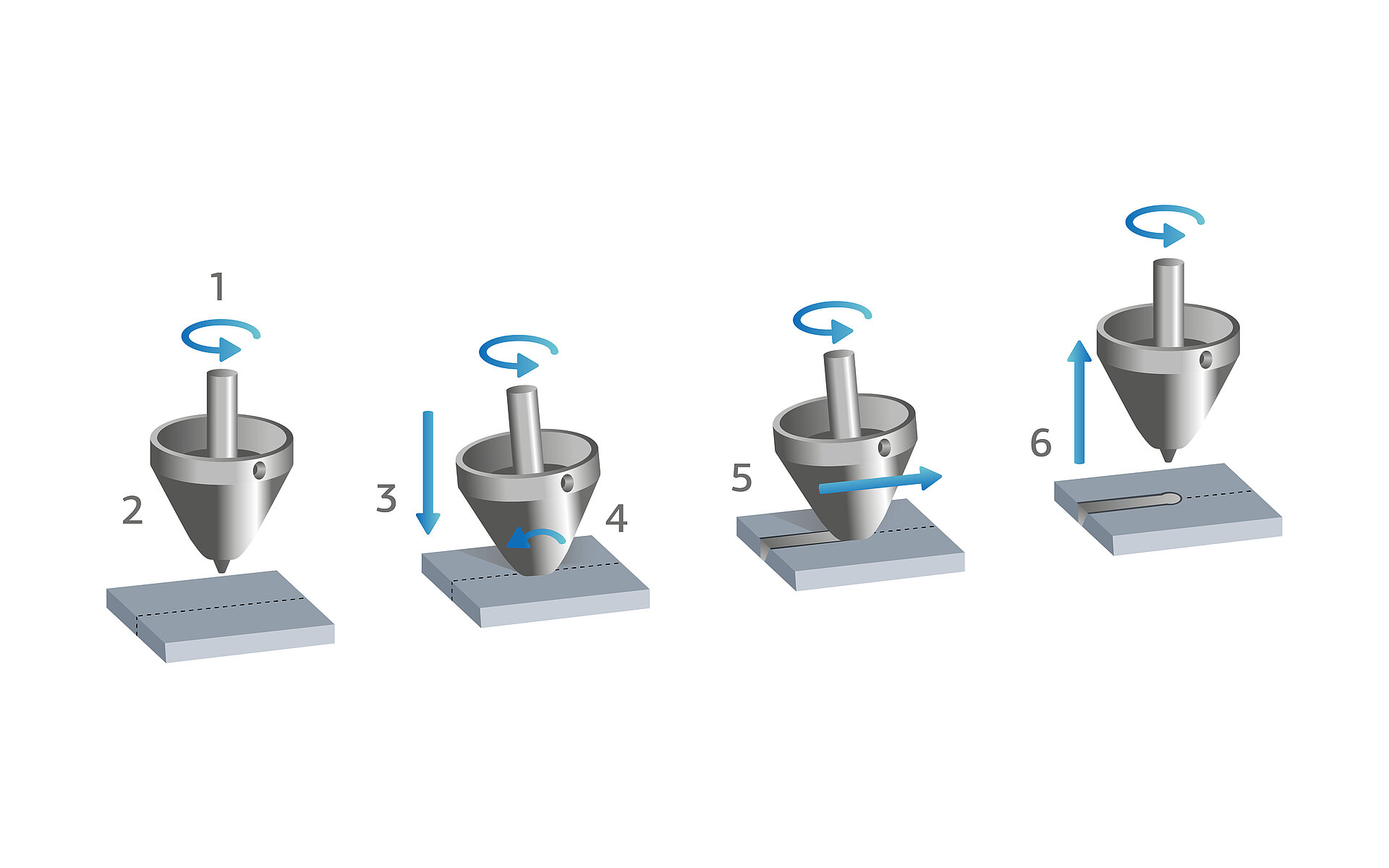

The special feature: The welding tool has a two-piece design and the tool shoulder slides over the weld seam without rotation.

The two-piece friction tool with rotating friction pin and non-rotating shoulder provides many advantages:

- Significantly reduced process forces (50%)

- High path dynamics

- Low heat input

- The welding depth is variably adjustable

- Shoulder geometry can be adapted to the joint geometry

DynaSTIR tools for friction stir welding processes also allow extremely delicate, gentle work. That's because the tool shoulder glides over the weld seam without rotating. This is possible because of a force-controlled process with high-precision sensor technology in the welding head and an integrated 0 - 5° swivel axis.

“Our ultimate technological goal is to ensure that our customers always achieve the best possible weld seam and surface qualities. For this purpose, either universal, widely tested standard tools for generalized applications can be used or individual adaptations to special customer requirements can be made. The friction tools with stationary shoulders further developed by Grenzebach offer an especially wide range of possibilities for tailoring and optimizing specific applications.”

Friction stir welding – a green technology

Protects employees

Dust, gases, fumes, radiation – friction stir welding doesn’t produce any of these. This ensures a healthy workplace. In addition, the technology is quieter than conventional welding processes, and friction stir welding is CO2-free.

Conserves resources

Auxiliary materials such as shielding gas, powder or welding wire are not required. The purchase and storage of operating materials are nearly eliminated. In addition, energy consumption is significantly lower than with classic welding processes.

Going green

Media-tight battery trays or heat exchangers – our technology is used to create important components for electric vehicles. Mobility with green power – an important contribution to the energy transformation and climate protection in practice.

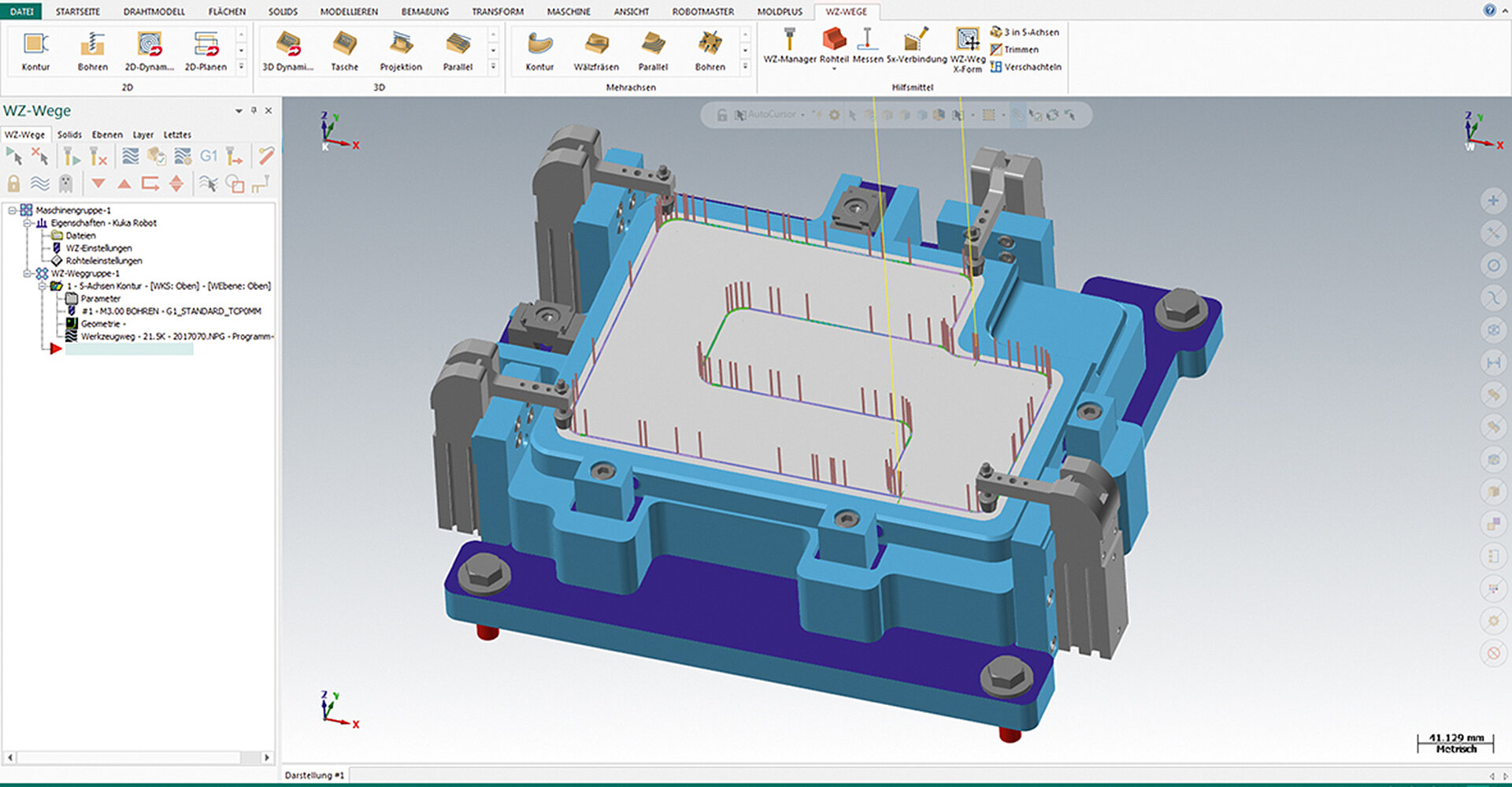

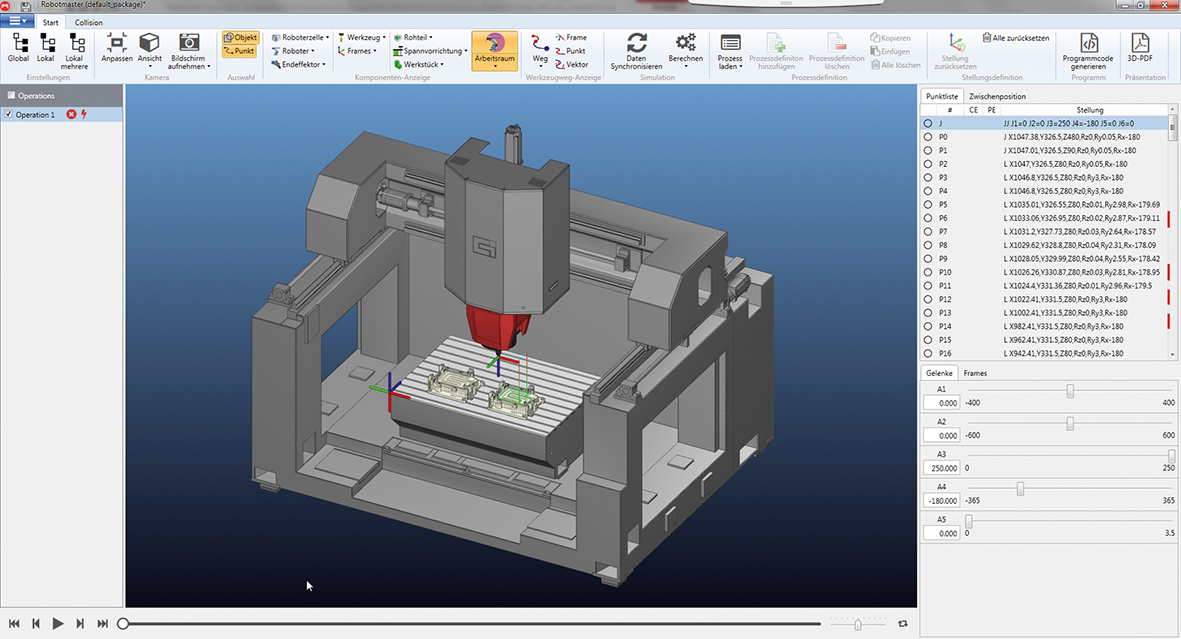

From 3D Model To Finished Welding Program In Just A Few Clicks

Professional CAD/CAM

The programming software specially developed for friction stir welding processes makes it easier for users to create welding programs. In addition to the weld path and the FSW process parameters, control over clamping devices can also be programmed in the CAD/CAM environment. Programming is carried out offline on a separate PC so it doesn’t slow down the system. The finished welding program can then easily be installed onto the system via a USB or network connection.

- Import of 3D models

- Geometry selection and path definition in the 3D model

- Simple modification options for the path geometry

- Definition of FSW process parameters and changes for individual path points and segments

- Insertion of action points in the weld path

- Collision detection of tools and parts

- Reachability check

- Possibility of importing different reaming tool geometries

- Creation and management of a tool database

- Documentation function and traceability of parameter or path changes, for example

Further solutions

Friction stir welding

For North America

Your Contact Person: John Fluker

Do you have questions about friction stir welding? Would you like to know whether a new idea can be implemented with FSW? Or do you need support in selecting a system? Please contact us. We'll be happy to advise you!

For all other regions

Your Contact Person: Sahin Sünger

Do you have questions about friction stir welding? Would you like to know whether a new idea can be implemented with FSW? Or do you need support in selecting a system? Please contact us. We'll be happy to advise you!