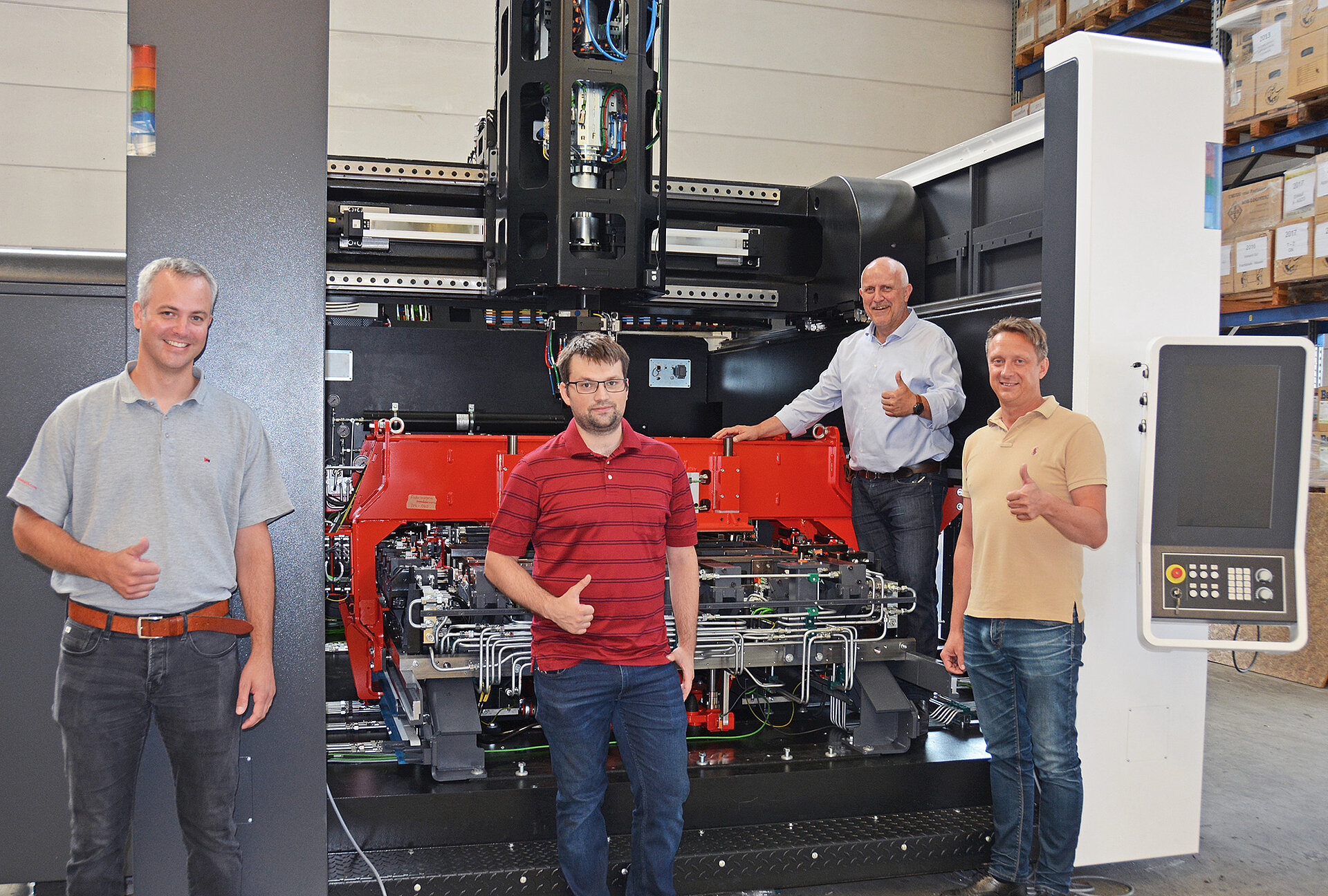

TPV AUTOMOTIVE and Grenzebach helping to shape the future of mobility

The project:

Customer:

TPV AUTOMOTIVE, headquartered in Novo mesto, Slovenia, has more than 60 years of experience in the automotive sector. The supplier for tier-1 currently employs more than 900 people.

Customer challenges:

Meeting high OEM demand for battery trays while integrating a fast yet robust process that achieves reliable and repeatable weld quality across the entire work process in the existing production line.

Solution:

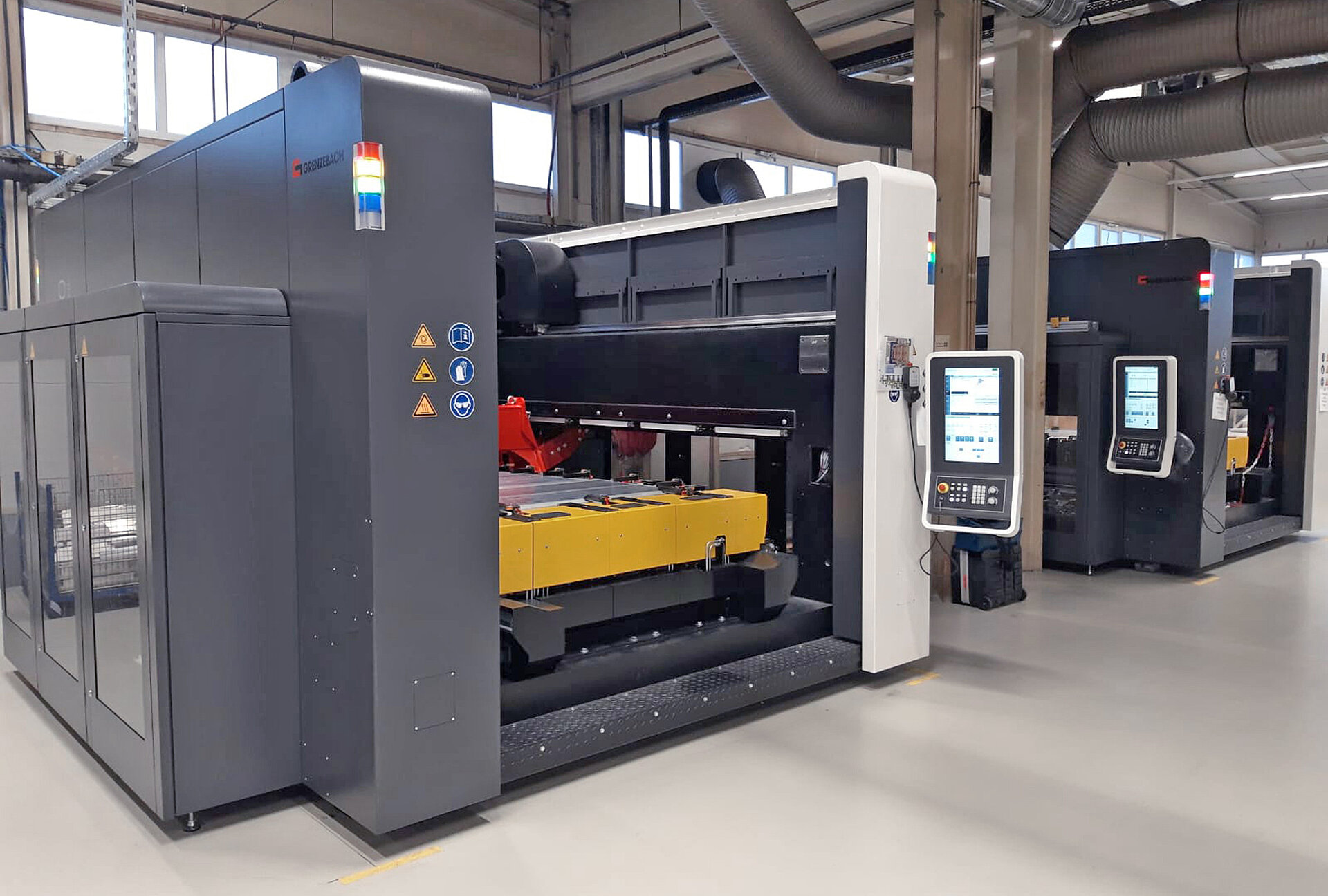

Integration of more four-axis gantry systems into the existing automatic serial production line at the production site in Brežice, Slovenia.

Solution package:

- 6 gantry machines type DSM 24-14 and DSM 30-14 with HYDROPOL® machine bed

- MonoSTIR welding tool for a high welding depth

- Prototyping, planning, assembly and commissioning

Benefits for our customer

Performance: 3,000 components per week

High axis dynamics and precise weld path guidance

Reliable and repeatable weld quality

Smooth integration into the existing automatic production line

“Alongside the high weld seam quality, the speed of the process steps is naturally decisive in serial production. Grenzebach's technology has completely convinced us with regard to these two important criteria.”