Solutions as robust as good wood

LIGNA takes place in Hanover, Germany, from 22 to 26 May 2017. It spans the entire value chain of woodworking activities and at the same time is a marketplace for innovations in the building materials sector. At its Stand E58 in Hall 26, Grenzebach focuses on innovations in veneer drying, automated guided vehicles for intralogistics applications, and production technologies for energy efficient building materials.

The Grenzebach product range covers a variety of systems, from complete veneer production lines with scanners and stackers to individual dryers with feeders and manual unloading stations. With over 400 of its wood veneer production systems in use worldwide, Grenzebach is among the world's leading suppliers of plants and systems for this industry.

To name just one of many special features: thanks to the special sinus system in the Grenzebach belt dryer, even beech or poplar veneers, which have a tendency to become wavy, will remain flat and smooth. "Our customers appreciate distinctive features and details of the machinery that make it sturdy, durable and highly reliable," says Michael Meyer, Director Wood Technology. Here are two more examples: Hot-dip aluminised sheets prevent corrosion.

Wet and dry end seal sections in the roller dryer are supplied with pressurised pre-heated air to prevent resin from accumulating on the dryer walls in the infeed and outfeed areas.

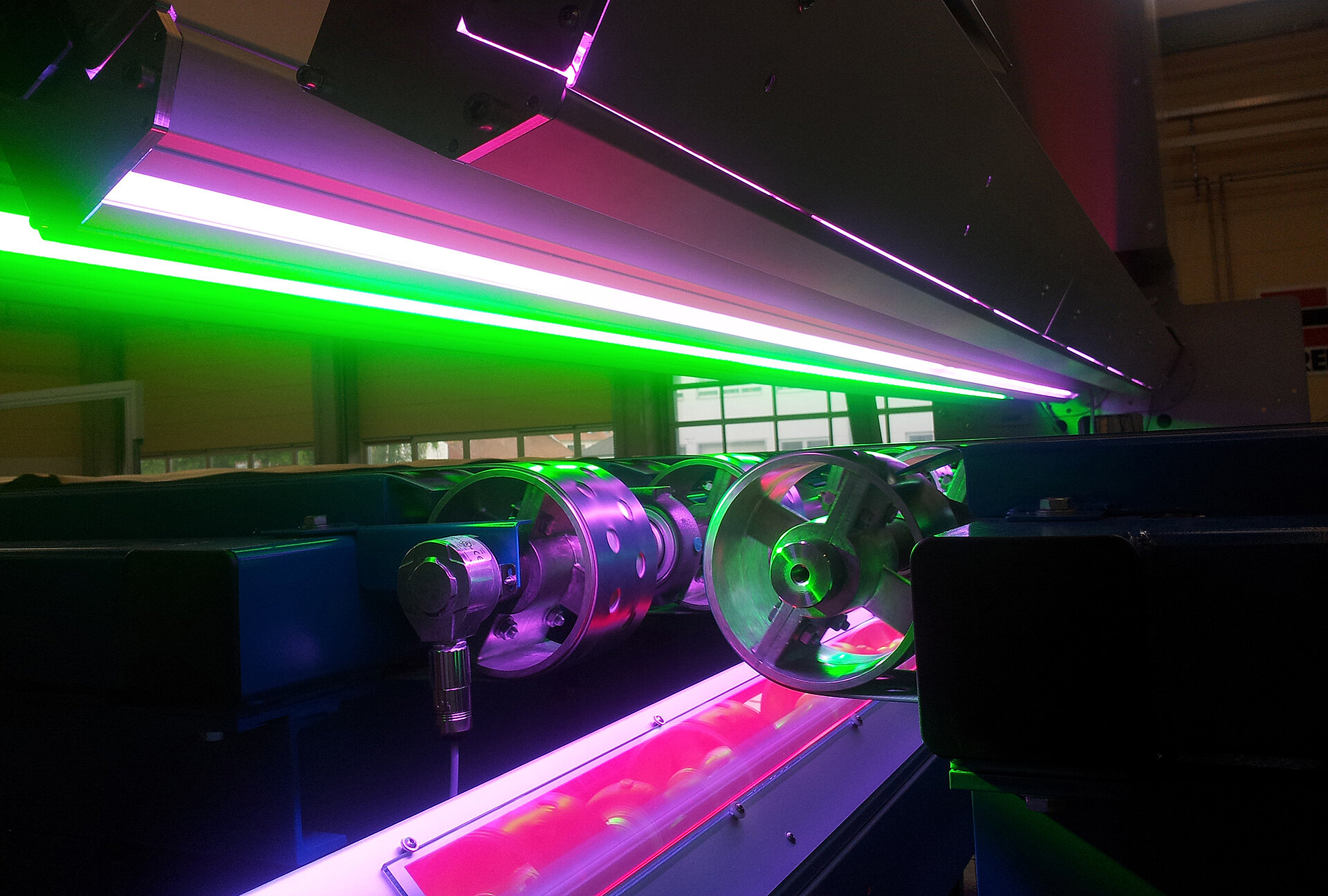

Modern dryer lines with automatic stackers handle large volumes of differently sized veneer sheets. An essential component in this process is the Grenzebach FPI veneer scanner for continuous and reliable quality grading. The continuous scanner detects all defects and quality criteria that are relevant for grading and sorting the veneers, and within seconds the system determines to which stacking station the scanned sheet will be sent. Visitors at LIGNA can see a scanner with Multi-Channel Technology in action.

From woodworking to intelligent handling of furniture elements: For the Nolte group, Grenzebach has equipped a new order picking warehouse for kitchen fronts with automated guided vehicles (AGV) as a standardised material flow and handling solution. Benefits of the use of the twelve AGV include: fewer errors, improved ergonomics and distinctly higher productivity in order picking. Which front must be where at what time exactly? Nolte's material flow controller and Grenzebach's fleet manager join digital forces and provide the answer. This is Industry 4.0 at work at Nolte, one of Germany's strongest kitchen brands.

From kitchens to complete buildings: Grenzebach supplies production technologies for all building materials that are needed in energy-efficient and modern building construction. From wood fibre insulation materials via loose fill cellulose insulation up to gypsum fibreboards. Grenzebach supplies complete production lines for "flat formed" building materials, covering all stages of innovative product manufacture, from the raw mat or board up to the warehouse . "We also integrate existing customer equipment into our production lines," adds Michael Meyer.

Speaking of integration: Grenzebach solutions are also on display at the stands of the Zimmer Group (Hall 11) and Steinemann Technology (Hall 26).