Mission: Additive Manufacturing for serial production

From medical goggles to splitters for ventilators: Impressive 3D printing initiatives have emerged around the world during the last months to produce much-needed items to deal with COVID-19 – companies as well as universities and volunteer organizations got involved. "Many dedicated individuals around the world have demonstrated that 3D printing can bridge supply gaps quickly and flexibly. That applies to both the response in a pandemic and manufacturing." says Oliver Elbert, Head of Business Development at Grenzebach. "To fully unleash the potential of additive manufacturing in the long term, intelligent automation and networking of the equipment is particularly important. This is why we’ve intensively been working on appropriate solutions since several years." Currently, Grenzebach contributes amongst others to the lighthouse project POLYLINE. At the virtual trade fair formnext connect the Grenzebach automation experts will be available for technical discussions and in-depth consultation.

Industrial 3D printing intelligently organized

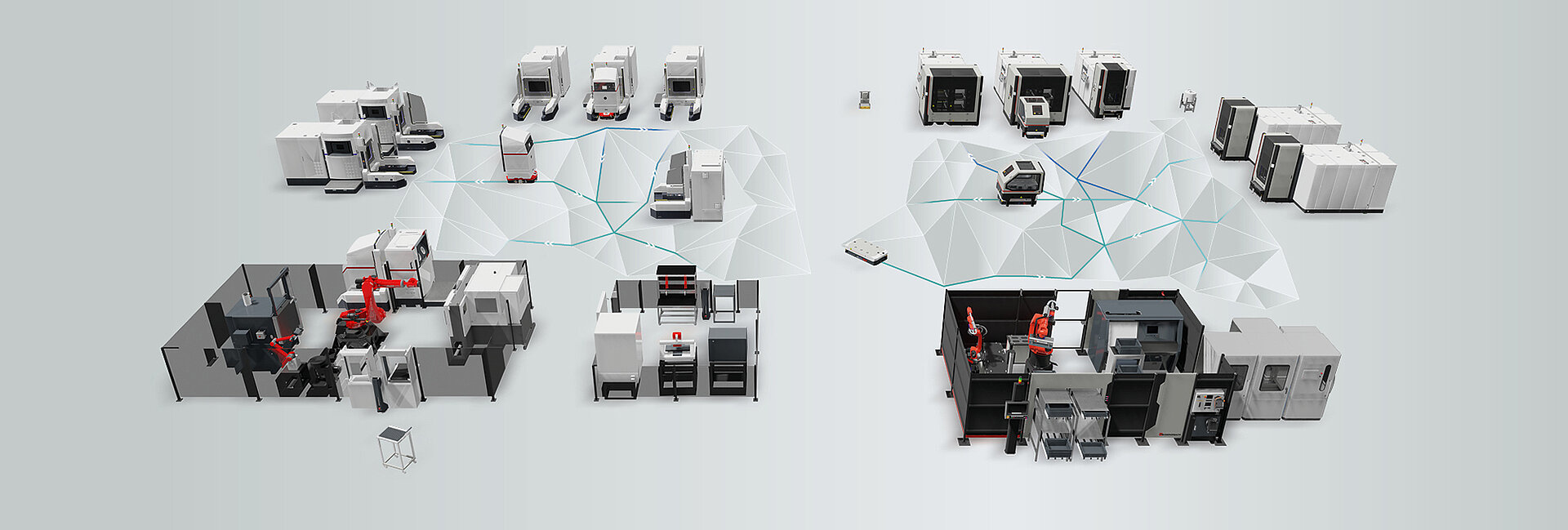

Numerous process steps of varying duration make additive manufacturing a complex matter. Users benefit from automating processes and ensuring optimum material flow between individual devices such as printers, saws, furnaces and finishing systems. Grenzebach focuses on holistic solutions for industrial 3D printing, including up- and downstream production steps. The customer-specific automation solutions use Grenzebach equipment and also integrate third-party systems: From Automated Guided Vehicles (AGVs) and robot cells to gripping technology and inspection systems, Grenzebach offers everything that is needed for intelligent additive manufacturing. In addition to consulting services and hardware, the company's digitization platform SERICY also allows for each individual solution to be digitally mapped and controlled. In this way, processes can be optimally integrated, data is made available to all departments in the company - and the system is open for future App developments. The focus is to support economical serial production.

Lighthouse Project POLYLINE

This also is the subject of the POLYLINE research project, in which Grenzebach is currently participating. The aim is to develop an automated and efficient production process for additive serial production with polymer-based laser-sintering (LS). It is one of six projects funded by the Federal Ministry of Education and Research within their program "Line Integration of Additive Manufacturing Processes" of Photonik Forschung Deutschland. Interested parties can find out more about the project findings and next steps at formnext connect. "Working with 15 industry and research partners on a next-generation digitized production line gives us the opportunity to contribute and further sharpen our process knowledge. The findings from this lighthouse project will be valuable for practical applications beyond the automotive industry," says Elbert.

Active occupational health and safety

Automation solutions make 3D printing not only more economical, but also safer. Organizations such as the German Federal Environment Agency point out that employees can be exposed to fine dust and nanoparticles, especially during post-processing of 3D printed components. In addition, there are special challenges resulting from the processes themselves. For example, additive manufacturing techniques for metals require a protective gas atmosphere. "Automated handling and transport technology massively contributes to occupational health and safety," says Oliver Elbert.

“To fully unleash the potential of additive manufacturing in the long term, intelligent automation and networking of the equipment is particularly important.”

Grenzebach experts are available virtually

Whether you're a printer and peripheral manufacturer, an experienced user, a novice in industrial 3D printing or an experienced consultant: Grenzebach's experts are looking forward to the professional exchange at formnext connect. "We would have very much appreciated the face-to-face exchange with our partners and all interested parties during the physical show in Frankfurt. But given the circumstances we of course welcome the responsible action of the organizer mesago in taking formnext to a digital stage this year," says Frédéric Erben, Head of Corporate Strategy & Communications. "Our entire additive manufacturing team will be available virtually for discussions and to demonstrate our solutions.” On Thursday, 12 November, 10 - 10:30 a.m., Oliver Elbert and the VDMA Working Group Additive Manufacturing will present a case study from Siemens, Grenzebach, Issberger and Azo with the title "AM for Industry - from Manual Work to Industrial Production | Bringing down cost-per-part by a high degree of automation”.