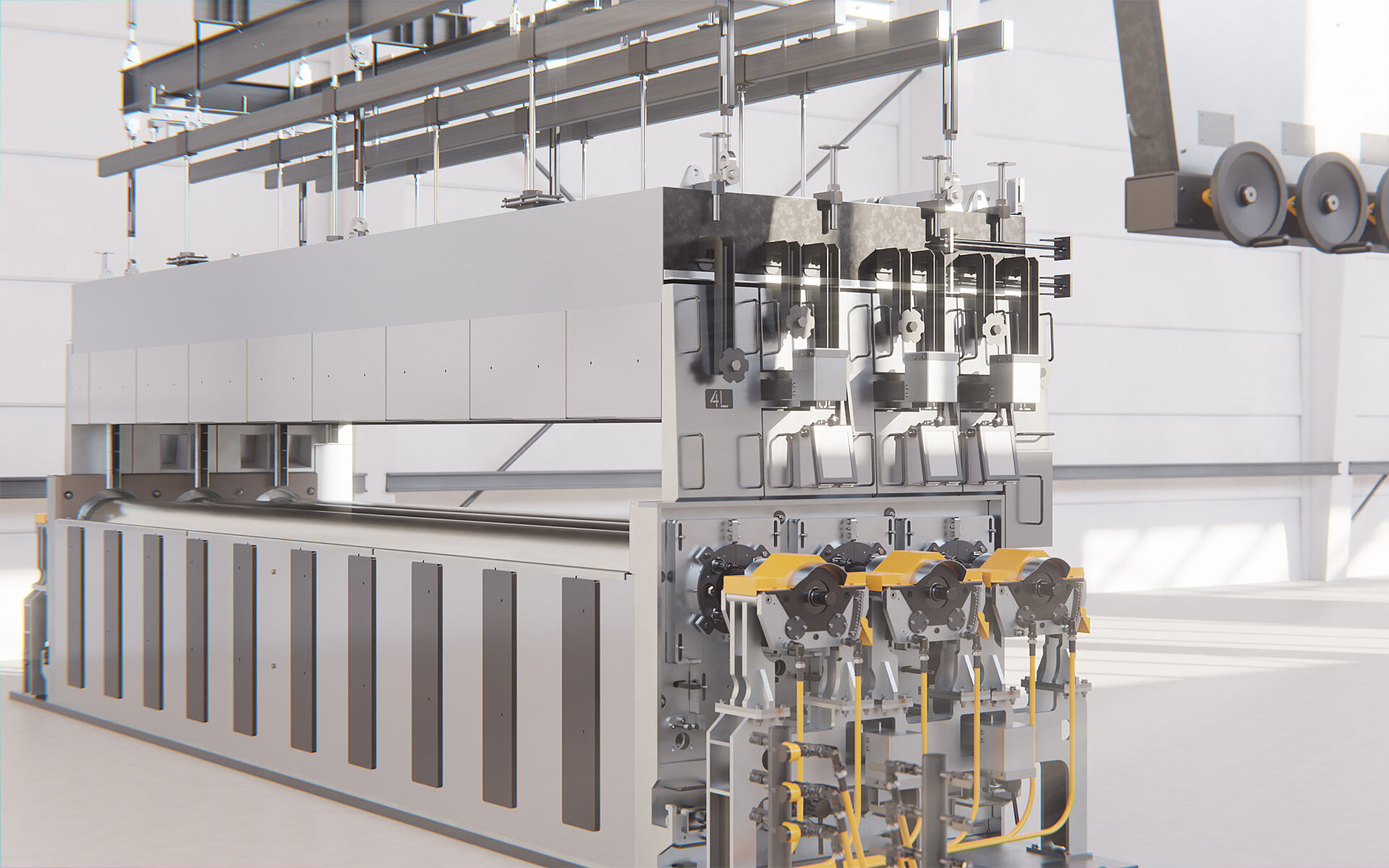

Making the hot end even more efficient with Grenzebach's optimized dross box

- New dross box creates simplified maintenance and local, decentralized control

- Numerous inquiries and positive feedback from the industry

- Dross box demand increased especially in the thin glass sector

HAMLAR/Germany. The process of glass production is complex – and an aggravating factor in this industry is also a growing shortage of skilled workers. This makes it all the more important to make the operation of the production plant as simple and maintenance-friendly as possible.

With the new dross box, which was presented for the first time at Glasstec 2022, Grenzebach, a leading company in the industry, found a solution to this issue and at the same time set a milestone: The new design scores with outstanding user-friendliness and safety, both in operation and maintenance. Franz Krommer, Product Manager Glass at Grenzebach, explains the background to the redesign: "Glass plants have to run continuously, especially in the hot end. Downtimes must therefore be kept as low as possible. Grenzebach has therefore made significant changes in the area of roller technology and the housing. As a result, plant operators can now maintain and operate the dross box even more easily. This saves a lot of time in day-to-day production, increases process reliability, and in turn boosts efficiency and productivity."

More production flexibility due to quick height adjustment of the lift-out rollers

Previously associated with a great deal of effort, now with significant simplifications during operation: The simplified and fast height adjustment of the lift-out rollers enables individual adaptation of the curve geometry to the needs of production. In addition to greater process reliability, this ensures more flexibility, especially when producing different glass thicknesses. With the new dross box, this height adjustment is fast and at the same time safe without time-consuming loosening of the bearing caps. Special seals make this possible. The height adjustment is carried out with individual direct drives.

This is an innovation that Krommer says customers are particularly excited about: "We've already received a lot of positive feedback for our optimizations."

As an additional expansion stage, Grenzebach offers an automated version in which all settings for the corresponding glass thickness can be saved and retrieved at any time.

Flexible roller mount

Another advantage is that the dross box can be fitted with different types of lift-out rollers: steel, coated steel and ceramic are all equally possible. This gives customers greater flexibility in their choice of rollers.

Simple and safe maintenance

Changing the graphite bars is now also much less work. The rolls are permanently cleaned via multi-part graphite bars with pneumatically adjustable contact pressure to ensure a clean process.

With up to 850 °C also suitable for thin and special glass

The standard version of the dross box is designed for a maximum temperature of 650 °C, the premium version even covers application ranges of up to 850 °C – important above all in the production of thin glass or special glass. This high-temperature version is so far unique on the market. "Particularly among thin glass manufacturers, we have seen high demand for our dross box in recent months," says Krommer.

Optimum atmosphere separation thanks to new curtain concept

An important task of the dross box is to separate the protective atmosphere in the tin bath from the atmosphere of the cooling channel. This is done by means of graphite strips below the rollers and by curtains above the glass, as well as through the apply of Nitrogen curtain sealings. The new dross box has four height-adjustable curtains with special suspension, made of a particularly heat-resistant material – so they do not deform and remain gas-tight even at high temperatures.

Get your own picture, live and in color

Interested parties can be shown the functions of the new dross box in the year-round Grenzebach showroom "365 Days of Grenzebach World" on site in Hamlar or digitally: at glasshandling@grenzebach.com or +49 906 982-2000, the Grenzebach Group's glass experts will be happy to arrange an individual appointment.