Japan – Premiere for the Grenzebach Friction Stir Welding technology

Stirred, not melted – live in Tokyo.

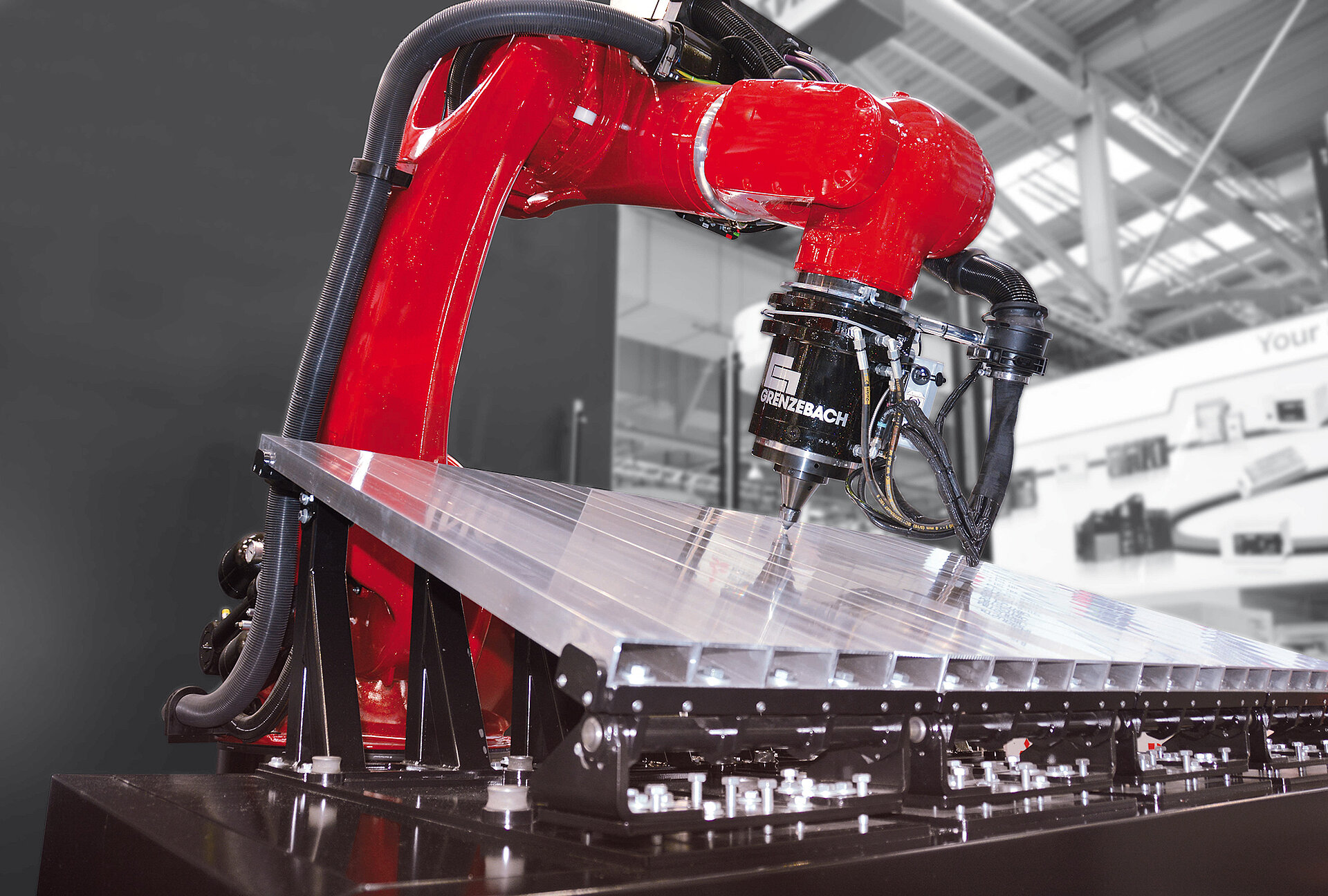

At the Japan International Welding Show, Aichi Sangyo presents the Friction Stir Welding from Grenzebach for the first time to the Japanese market. Friction Stir Welding, FSW for short, allows the bonding of pure metals, alloys and mixed compounds with highest quality; a great advantage compared to traditional welding processes is that with FSW the material is not melted which means less heat is introduced; unfavorable results, such as high component distortion, pores and heat cracks, which increase the risk for leakage, are avoided.

Strong market position in Eastern Asia

„With Aichi Sangyo we have gained a strong and reliable sales partner, who knows the Japanese market in and out and is very well positioned within the automobile industry“, says Michael Sieren, Head of Sales for Friction Stir Welding at Grenzebach. At the Japan premiere at the International Welding Show, Mr. Shuichi Yamana, General Manager East Japan Sales Dept. from Aichi Sangyo states: „With the Grenzebach FSW technology we are able to extend our portfolio adding an innovative joining technology. We can offer our customers equipment technology to exactly match their product requirements and achieve a perfect welding result."

Innovations at the in-house „Aichi Sangyo Techno Fair“

Aichi Sangyo, founded in 1937, imports and sells equipment for well-known manufacturers of welding technology, metal processing and additive manufacturing. Their headquarters are in Tokyo with additional locations in Nagoya, Kansai and Hiroshima. A location was established most recently in Sagamihara. At the plant opening with an in-house fair, a FSW expert from Grenzebach will demonstrate possible applications and innovations of this technology.

The sales cooperation between Grenzebach and Aichi Sangyo was initiated during last year’s “Schweißen & Schneiden” in Düsseldorf. At the time, Grenzebach celebrated two premieres of this innovative joining technology: the new 4-axis FSW machines DSM1400 & DSM2400 as well as the DynaSTIR FSW welding head generation.