Grenzebach presents SERICY.GBS: The innovator successor to PPC for networked glass production

- SERICY.GBS will replace PPC as the control system

- This integrated digitalization platform offers hardware, system architecture, data infrastructure and application solutions specifically for the glass industry

- Glass manufacturers can individually choose the right solutions for their needs

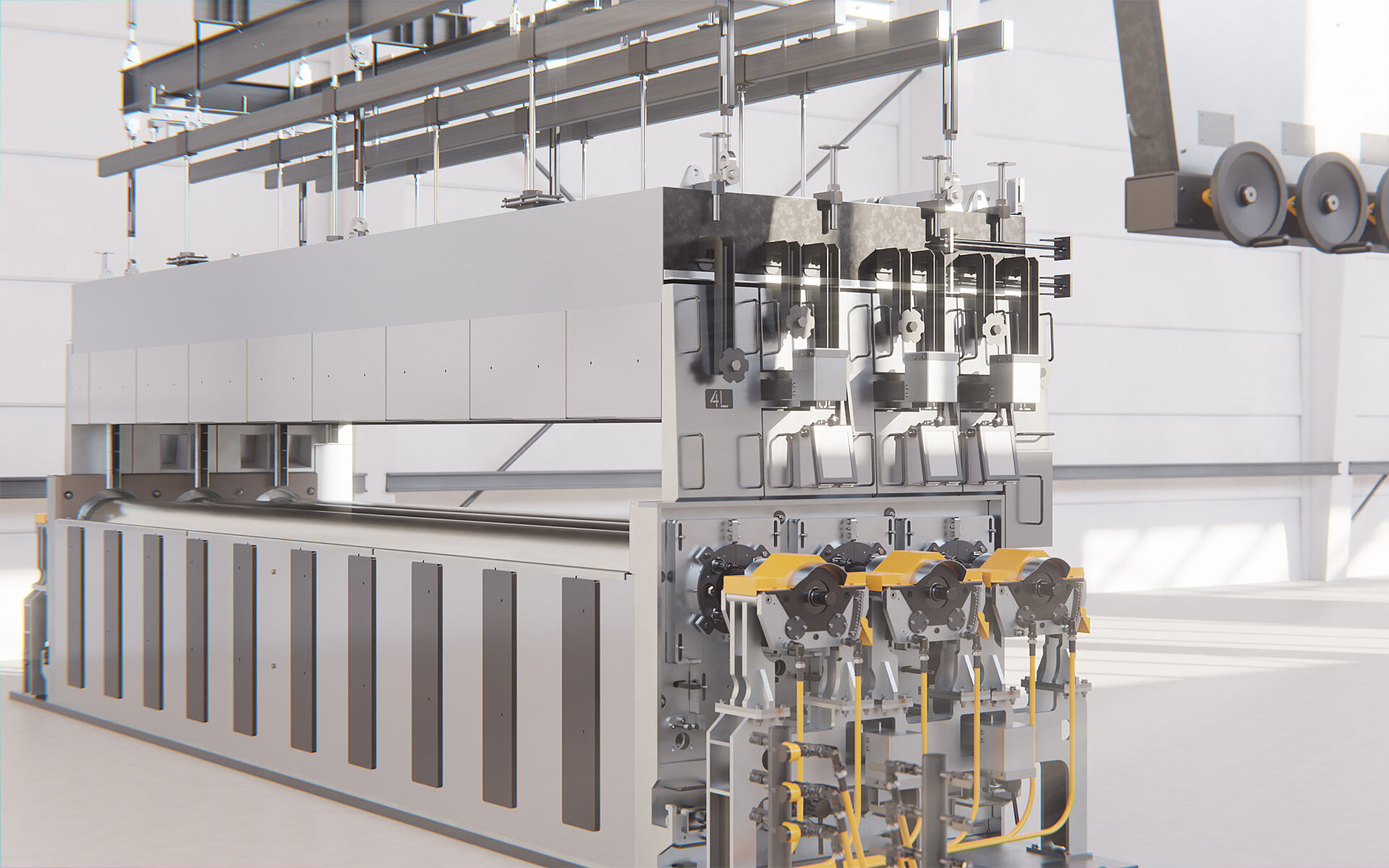

HAMLAR/Germany. By launching SERICY.GBS as an integrated digitalization platform, Grenzebach is setting new standards in glass production. With this scalable, open digitalization suite, SERICY.GBS is opening up completely new potential areas of optimization and will replace the previous PPC (Process and Production Control) control system.

"Digitalization plays a key role in achieving new efficiency gains in glass production. Technologically speaking, our systems are already at a very high level, so the scope for optimization is becoming smaller," explains Peter Seidl, Head of Product Management Business Unit Glass at Grenzebach. By taking an integrated and holistic view of processes that were previously treated separately, digitalization will be a game-changer in glass production. It will provide operators with deeper insights into the production process. By aggregating data and its analyses, this will enable system-aided and more targeted decision-making to increase productivity and product quality and to unlock further efficiency potentials.

SERICY.GBS: The integrated digitalization platform for the glass industry

With SERICY.GBS (Glass Business System), Grenzebach is presenting an integrated digitalization platform that is specially tailored to the challenges of the glass industry. Compared with previous control and optimization systems, SERICY.GBS networks individual production processes along the entire value chain. This means that information from the production process is continuously collected, made centrally available and analyzed. Consequently, SERICY.GBS will become the central nervous system of the production plant.

SERICY.GBS as a complete package – the entry point for digitalization

SERICY.GBS is part of Grenzebach's SERICY digital ecosystem and provides a comprehensive package of hardware, system architecture, data infrastructure and application solutions for various scenarios – and has been specially designed for glass manufacturers. Its interfaces to any subordinate or superordinate system enable you to make a profitable and quick start to digitalization. Due to its high degree of compatibility, SERICY.GBS is suitable for new and existing systems and its scalability means that it can optimally adapt to future requirements. In addition, SERICY.GBS is an intuitive, web-based user interface that supports a range of different screen sizes, as well as mobile end devices and wearables.

SERICY.GBS takes a modular approach. Glass manufacturers can choose from a wide variety of applications from the SERICY.GBS package – to suit their requirements. The applications are structured in functional clusters that glass manufacturers can individually choose from for a tailor-made package.

Selected clusters and their application solutions

As part of the SERICY.GBS digitalization suite, the SERICY.assist cluster offers a choice of assistance solutions that greatly help system operators to achieve a responsible approach to work. These solutions pave the way for reducing response times and errors.

A key element of SERICY.assist is the use of real-time notifications where immediate messages are triggered in the event of critical incidents or deviations in the production process. These notifications are generated by, among other applications, those of the SERICY.analyze, module – where in-depth analyses and evaluations of process data, partly assisted by AI models, are performed.This enables users to make system-aided decisions based on evaluated data and helps system operators to identify relationships and trends that they would normally be unable to due to the abundance and complexity of the information. Moreover, glass manufacturers can also benefit from efficient recipe management. Users can save specific parameters and recipes in SERICY.assist Recipe Manager, which, for example, means that you can directly apply the relevant settings when automatically adjusting the thickness of machines.

The applications of SERICY.optimize have been designed to improve product quality and to increase productivity – all while using minimal resources. They enable operators to define and manage various quality levels. In combination with the error data collected from the glass ribbon, optimization applications enable users to precisely adapt and control the cutting process. The CutOpt-System control element offers various optimization modes to achieve the required production objectives, whether it be maximum output, maximum product quality or prioritizing the production of particular formats.

In the SERICY.process section, the applications provide employees with comprehensive support for controlling processes, e.g. cooling and heating. SERICY.process takes production monitoring to the next level with its integrated anomaly detection. The system enables users to efficiently identify anomalies in the production process by using advanced data analysis techniques. Processes, process stations and process parameters are continuously monitored using statistical evaluations and machine learning algorithms, such that glass manufacturers can respond to any deviations at an early stage and focus on product quality.

The applications of SERICY.report produce customized reports that provide all stakeholders with relevant information. Whether KPIs, graphics or simple reports – the applications of SERICY.report enable you to create customized dashboards in which information from the equipment and process condition monitoring is presented in a clear and visually appealing manner. In addition to creating specific reports concerning production, glass loss and layer data, SERICY.report uses the PlateArchive application to provide all of the available data about a specific glass sheet according to its ID, a time stamp or a current location.

Moreover, SERICY.GBS offers additional modules that can be flexibly expanded with applications according to the glass manufacturer's requirements. This makes SERICY.GBS a solid, integrated digitalization platform for the future of glass production – from providing support to operators, to analyzing operating data and directly optimizing production processes.

AI-assisted efficiency gains

Having experienced system operators is a crucial factor in the current world of glass production. They can monitor processes in a targeted manner and intervene if required. Traditional methods and, in particular, the use of artificial intelligence, offer new opportunities for error detection and optimization. SERICY.GBS already offers the first AI-assisted applications for these purposes, such as anomaly detection, CutForce Optimizer, CutToolChange Assistant and a glass stress predictor. This makes SERICY.GBS a valuable aid for workers in glass production – especially in times when skilled workers are increasingly scarce.

Upgrade options: Especially for existing systems

With its inexpensive packages and attractive payment models, Grenzebach also offers an extensive range of products and applications to implement the digitalization of glass production in existing systems. As a long-term journey partner to the glass industry, Grenzebach is therefore opening up new possibilities to existing glass manufacturers.