Grenzebach belt dryer dries veneers flat out

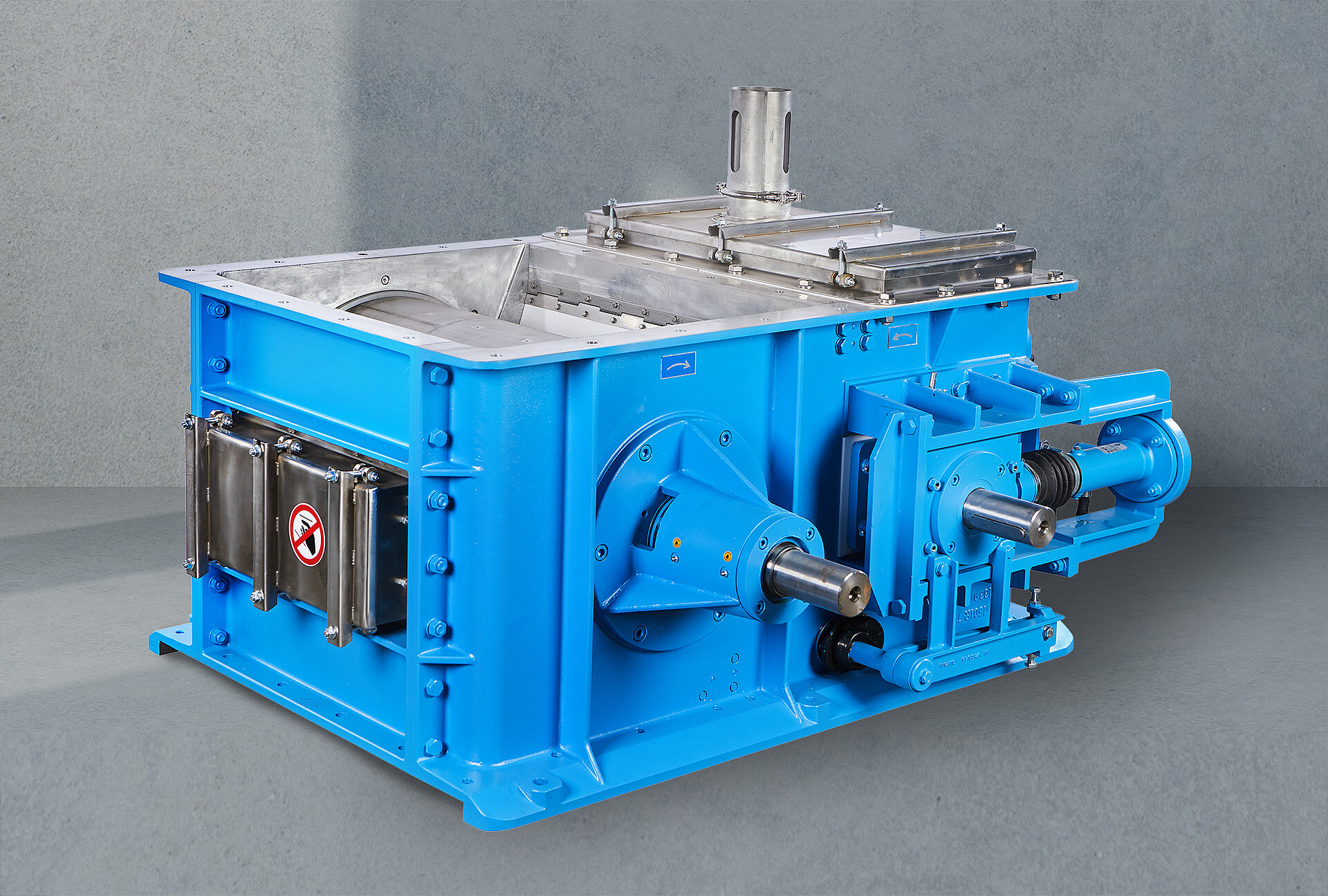

Perfect drying results even for difficult veneers: The special sinus guide system between carry and cover belt in Grenzebach belt dryers helps to reduce the waviness in particularly wet and difficult to dry veneer species. Further processing is thus made easier and less waste is produced. Roller dryers and belt dryers without sinus systems sometimes face the problem of so-called "omega" dry veneers that obstruct the run of the sheets and clog up the dryer.

A Grenzebach belt dryer has now helped Pollmeier to achieve a quantum leap in the manufacture of its BauBuche product. The properties of the 2-5 - 3-5 mm thick beech veneer mean that a special drying process is required – strength, smoothness, cracks are among the issues to be dealt with here. A reliable solution was needed for handling the veneers during dryer feeding, passage through the dryer and take off at the end of the dryer for stacking the sheets. The Thuringian company also requested that the BauBuche product, made form locally sourced beech, be dried to a very low final moisture (< 3% bone dry).

Pollmeier had experienced substantial drying problems for more than three years, including heavy corrosion and frequent clogging of the dryer. In trying to find a solution, Pollmeier first conducted trials with the beech veneer on a Grenzebach sinus-belt dryer supplied to a producer of poplar plywood in Italy. These trials were successful and Pollmeier placed an order with Grenzebach for the supply and installation of a sinus belt dryer at its location in Thuringia.

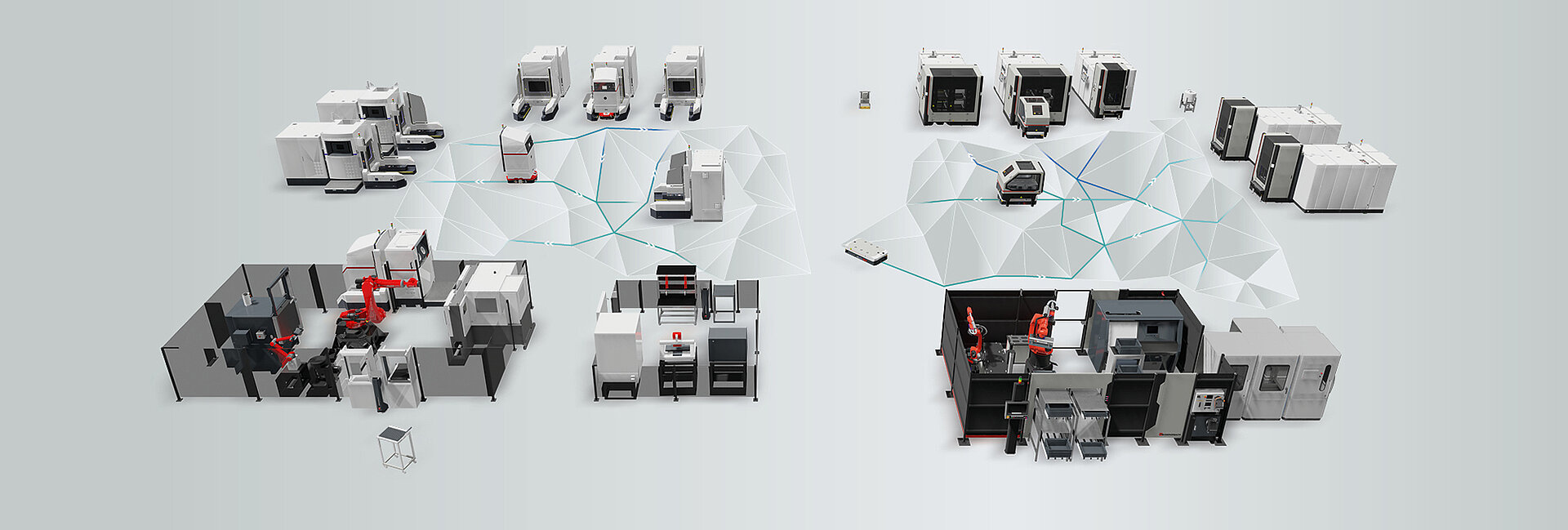

With over 400 of its dryers in use worldwide, Grenzebach is among the world's leading suppliers of plants and systems for the production of wood veneer.