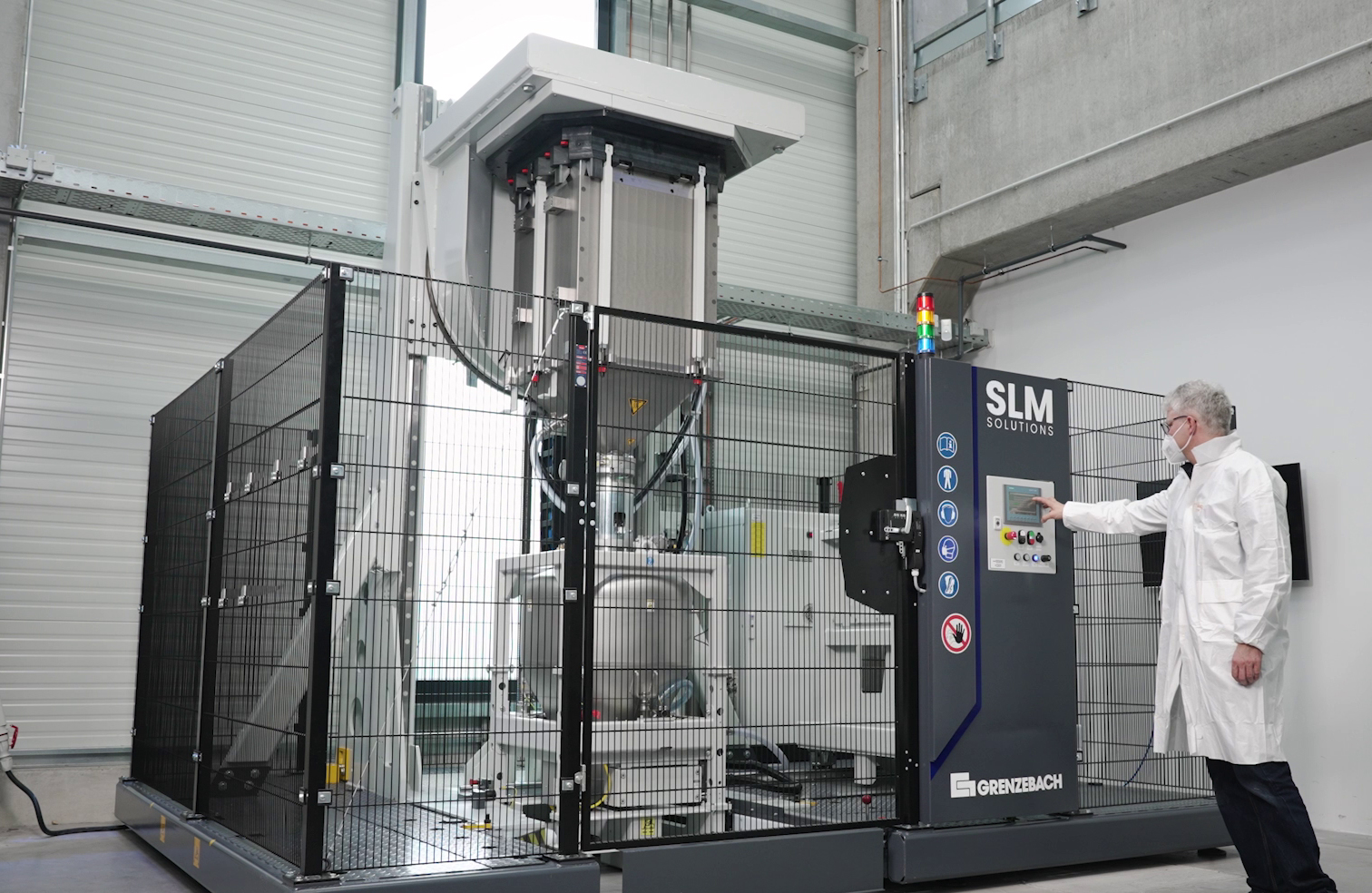

From challenges to solutions: Grenzebach Exchange P 500 systems

- Automated loading, unloading, and cooling, for efficient processes

- Boosting productivity by reducing downtimes

- Increasing operator safety by minimizing manual interventions

In the dynamic world of additive manufacturing, time is a valuable asset. Competition is fierce, the demand ever increasing, and requirements shifting and growing. The modern world is constantly moving forward, and businesses must move even faster to stay ahead of their competitors and in the game. Optimizing processes is crucial to increasing productivity and remaining competitive in the market. This poses a constant challenge for manufacturers in various industries, be it aerospace, automotive, industrial or medical products. The main objectives are to minimize the machine’s downtimes in order to increase the system’s efficiency, while preserving the high quality standards of your production. The solution to achieve this is simple: Automation. With the Grenzebach Exchange P 500/2 and P 500/4 solutions for 3D printers (Laser sinter systems), you can face this challenge with confidence.

Enhancing your competitiveness

Grenzebach‘s automation solutions are designed to address the issues of today’s additive manufacturing with a simple yet efficient concept: streamlining your processes by automating the loading and unloading of 3D printing systems, specifically laser sintering systems such as the EOS P 500, with integrated conveyor systems and shuttles. The results are tangible cost and time savings because the time between the individual build jobs is reduced, allowing for more jobs in a row. The safety of operators is also increased as the finished build jobs are cooled down on the buffer positions. These feature a temperature monitoring, with maximum temperatures of 250 °C. They also allow a cool-down outside of the printer and thereby minimize the need for human intervention.

Grenzebach’s solution is not limited to these specific printing systems but can be customized and tailored to meet the unique demands of other 3D printing systems as well. Your automation can be streamlined even more with the option to include docking frames and automated guided vehicle systems (AGVs).

The advantages for your production? With the Exchange P 500/2, our simulation reveals a significant boost in productivity for a single-shift operation model. Over the course of a year, build jobs with durations of 5 to 30 hours witness a substantial increase in productivity. By automating the processes and decreasing the downtimes, a 50 % increase in build jobs is possible.

Boosting your productivity, streamlining your operations – a case study

For a better illustration of the Grenzebach’s Exchange solutions, we will look at the following case study for the EOS P 500 with the Exchange P 500:

Our scenario features a single-shift, five-day week with build jobs averaging to 16 hours and 15 minutes. The ambitious target in this exemplary case was a significant surge in productivity: an over 50 % increase in build jobs per year using the existing systems, without the need to transition from the single-shift to a two-shift or 24/7 operation. The means to achieve this target is automating the loading and unloading processes with the Exchange P 500/2, or P 500/4.

In comparison

- Switching to a two-shift operation, without automation:

- Increase in build jobs per year: +20 %

- Increase in build jobs per year: +20 %

- Single-shift operation with the Exchange P 500/2 solution:

- Increase in build jobs per year: +51 %

- Increase in build jobs per year: +51 %

- Single-shift operation with the Exchange P 500/4 solution:

- Increase in build jobs per year: +83 %

- Increase in build jobs per year: +83 %

The numbers speak for themselves: in comparison, the implementation of the Grenzebach exchange solutions yield an astounding productivity boost while maintaining the single-shift operation. Traditionally, to achieve this kind of efficiency, a transition to a two-shift operation would have been necessary. With the Exchange P 500 solutions, you can keep your existing operational structures, relieve your employees, and still gain a competitive advantage. In addition, the machines’ downtimes are reduced, and the exchange of frames is a more flowing, smooth process.

Driving growth and innovation with Grenzebach

The world of additive manufacturing is constantly evolving, as is the need for intelligent solutions that enable you to keep up with this pace. Enhancing productivity, upholding quality standards – this requires innovative ideas and a shift away from outdated approaches. Grenzebach takes up this task with the Exchange P 500 solutions for laser sintering systems. By automating the loading and unloading of 3D printing systems, providing buffer positions for passive inert gas supported cooling of the build jobs, and minimizing human intervention, your productivity, and not to forget operator safety, are improved substantially. You can navigate your operation without the need to transition to a different shift system and still gain competitive advantages in the market. Grenzebach’s automation solutions are customized and innovative and can advance your production to stay on top of today’s many challenges.