Friction Stir Welding for Energy Revolution

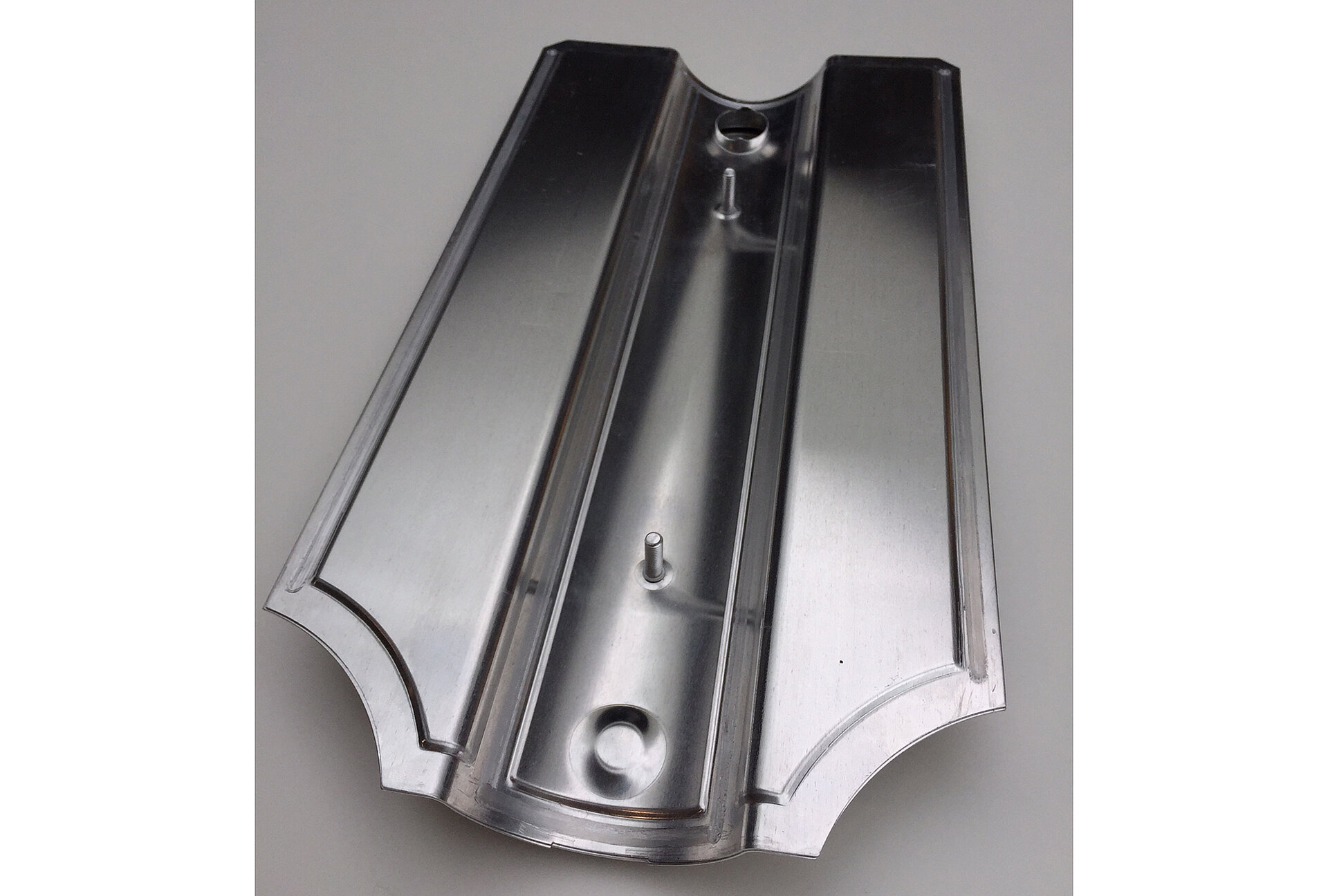

Water heating and treatment with solar power from your own roof is made possible with the “SolarPowerPack” from Nelskamp, headquartered in Schermbeck in North Rhine-Westphalia, Germany. “SolarPowerPack” provides a modern looking roof that is perfused by solar liquid. The heated liquid becomes the energy source for heat pumps or alternative energy storages.

The energy revolution on the roof requires solid and media-tight roof collectors and the exclusive Friction Stir Welding (FSW) procedure provided by Grenzebach allows connecting the aluminum punched parts with minimized distortion. When Nelskamp needed 6,000 aluminum connectors, the FSW experts at Grenzebach rose to the challange. "We process high-grade aluminum in a very thin mold; parts with a thickness of only 1 millimeter are welded with overlapping joints. Our Friction Stir Welding technology offers excellent performance", says Sales Director Friction Stir Welding at Grenzebach.

Compared to other welding techniques, such as electric arc or laser welding FSW does not use molten material and therefore requires less heat; this allows to avoid unfavorable results, such as high component distortion or pore and heat cracks which can increase the risk of leakages.

"For the production of our roof collectors we had been looking for the right technology and a reliable and experienced partner. With Grenzebach we have found both", says Christian Bremer, engineer for solar and photovoltaic application technology at Nelskamp. Once Grenzebach has completed their welding, the roof collectors are sent to a powder coating company to put on the required roof color; many different options, one single energy revolution.