Realize Your Individual Product Vision with Us

SOLUTIONS FOR THE FULL RANGE OF PLASTERBOARD PRODUCTS

We support you in meeting your market requirements with tailor-made production systems. We supply you with technology that specifically meets your customers’ requirements. Relevant product properties are therefore consistently the focus of our technical development.

From standard plasterboards to boards with higher requirements on fire protection or moisture resistance - we cover the diverse product range of plasterboards. With our many years of experience, our technical engineering, and our know-how we are happy to be your production and development partner for your individual plasterboard requirements.

From small-scale plants up to high-speed production lines, we supply facilities according to your capacity requirements.

“Modern building and design concepts with plasterboard inspire us and motivate us to ignite this raw material’s potential in manufacturing. That’s why we design production lines that ensure that your plasterboard performs as promised.”

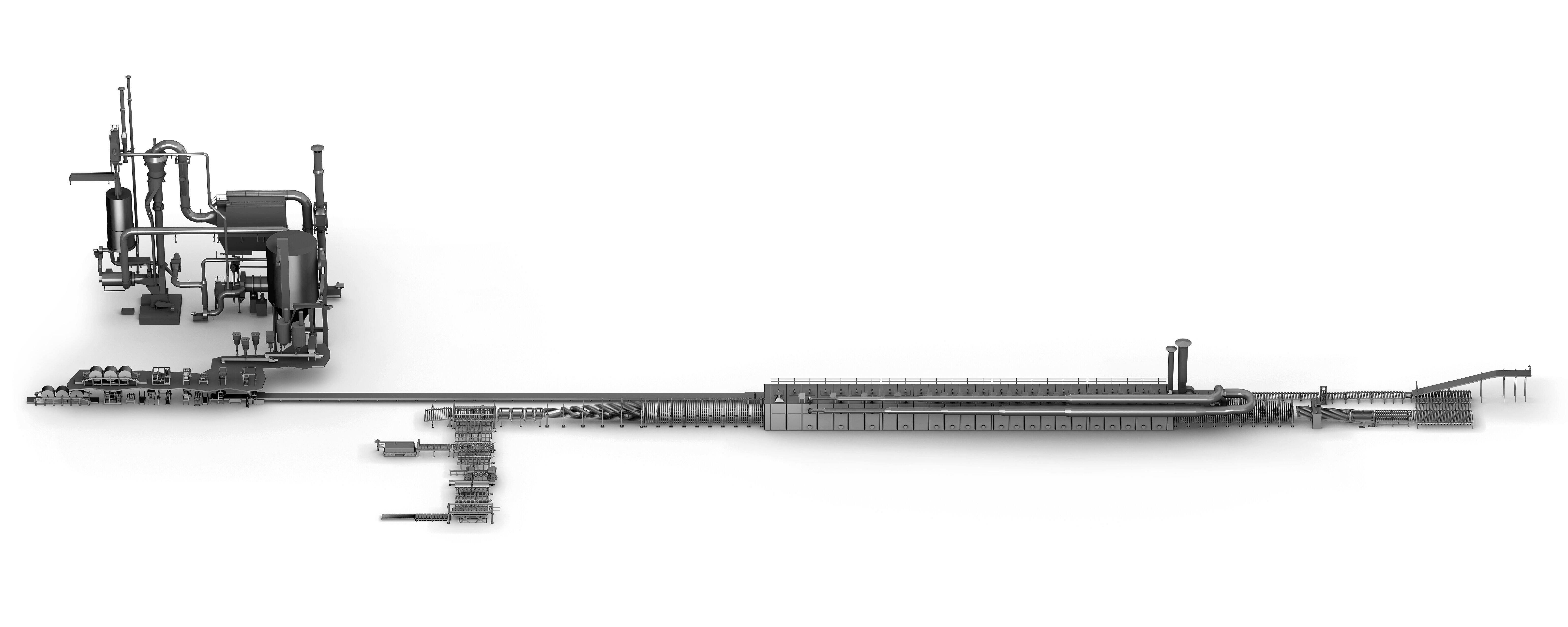

Grenzebach: Full-Line Supplier for Plasterboard Production

PLANT COMPONENTS FROM A SINGLE SOURCE

Technologies from Grenzebach cover the production of plasterboard in a harmoniously structured process, holistically and at a consistent quality level. From calcination to drying and stacking, we equip all process steps with tailor-made plant components that are dimensioned according to your capacity requirements. Our innovative solutions reflect the state of the art and optimally prepare you for future developments.

Seamless Integration into Your Value Chain:

Depending on your individual requirements, we can execute

- concepts for new plants

- the expansion of existing infrastructures

- the integration of individual machines

- the retrofit of your existing equipment

Calcining system

Mixing and forming

Paper handling

Stacking and packaging

Forming belt

Board dryer

Knife

Bundler

Drum Cooler

A Project of Superlatives: XINFA and Grenzebach Set New Standards in Plasterboard Production

Success Story

XINFA Group enters the Chinese plasterboard market with an annual output of 120 million square meters. XINFA relies on Grenzebach’s know-how for the efficient processing of synthetic gypsum from its power stations.

Spanish Market for Gypsum Plasterboard Captured Quickly in a Joint Effort

success story

Grenzebach provided comprehensive support to the Spanish gypsum specialist Escayescos in setting up its own production line for high-quality plasterboard – maximum cost-effectiveness and energy efficiency right from the start.

Your Partner on the Road to Success

WITH YOU ALL ALONG THE LINE

Far beyond the planning and implementation of a plasterboard plant, Grenzebach supports its customers holistically, right before and during the market entry phase. Our experts

- advise you on the financing of your project

- support the planning of buildings and infrastructure

- clarify questions about downstream logistics processes

- make their know-how available during market entry

- provide recommendations for personnel planning

- assist you with the procurement of materials

- take care of installation and commissioning

Our Services have already enabled many newcomers to get off to a successful start in the world of plasterboard production.

Your Contact Persons

Gypsum processing – a multi-layered process which we tailor to meet your needs. Get in touch!