Discover the Automation Potential of Your 3D Printing Equipment Now.

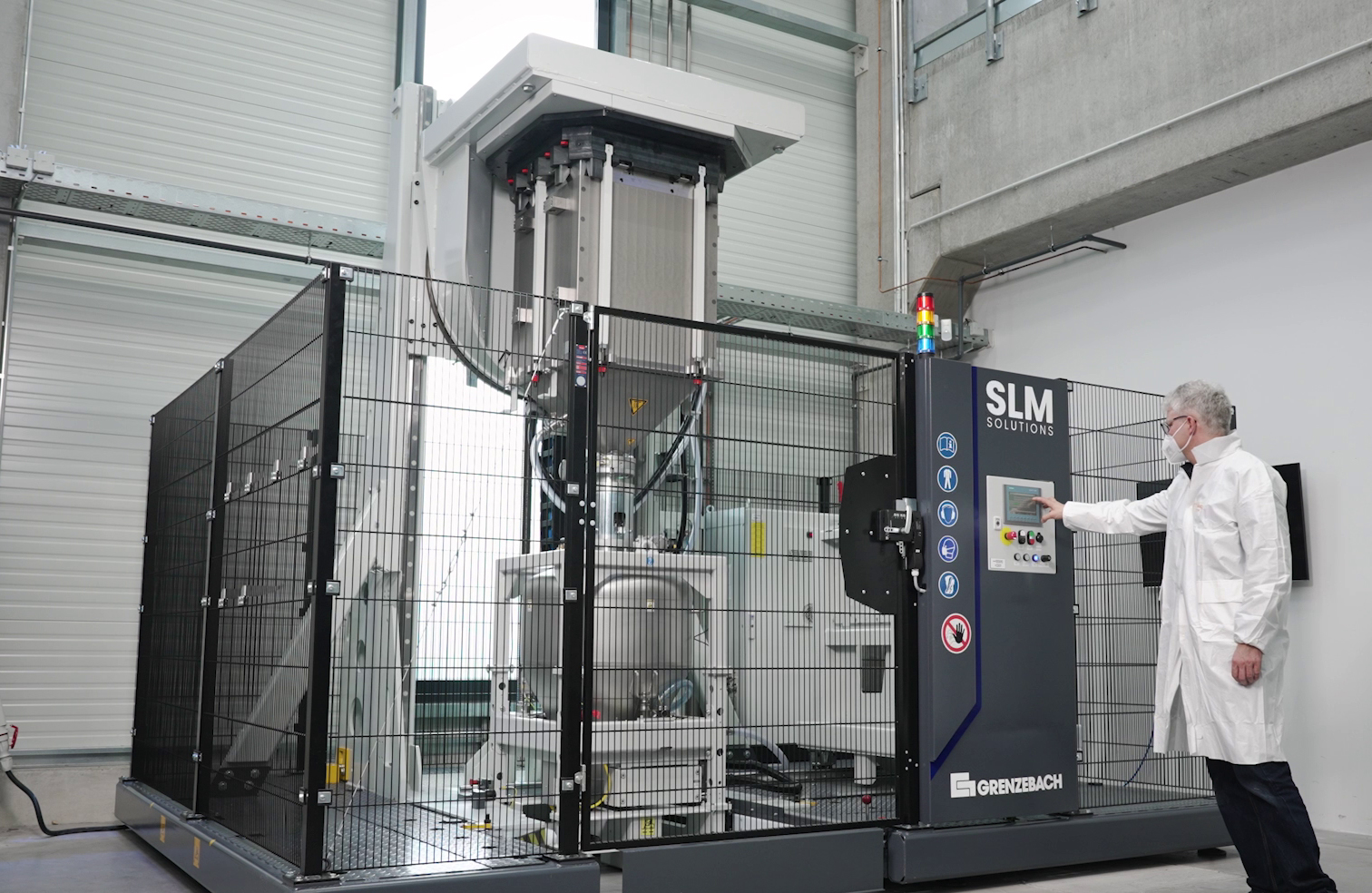

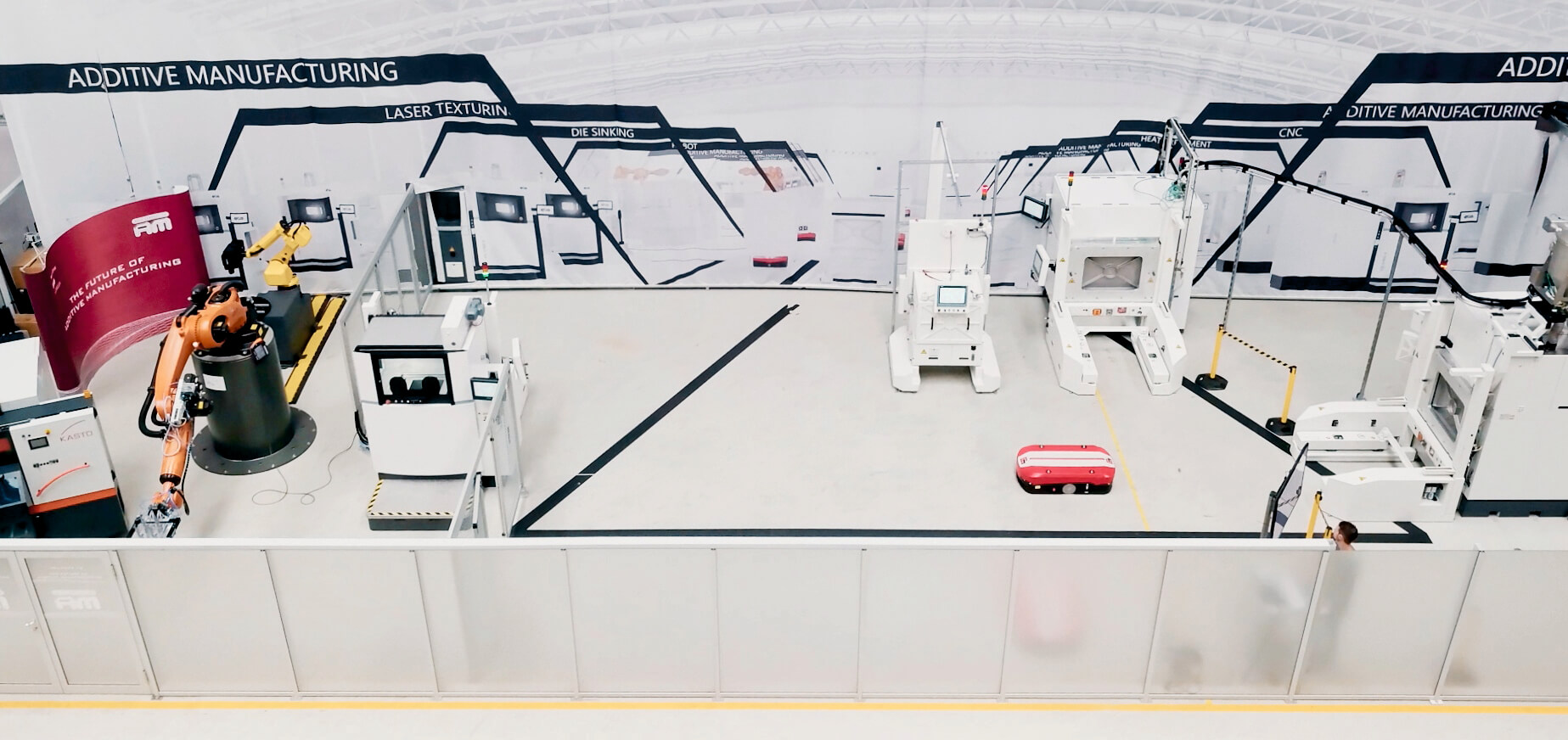

Embark on serial production with additive manufacturing: with innovative solutions by Grenzebach, you can optimize your workflow for metal or polymer components by efficiently utilizing your 3D printing equipment. Simultaneously, you are establishing a working environment with the highest safety standards.

Table of Contents:

FAQ

Three Reasons to Automate Your 3D Printing Equipment with Grenzebach:

More Efficient Processes

Automation interconnects process steps with different processing times, such as those that occur in printing, pre- or post-process, intelligently and reliably. This enables you to achieve an optimum production flow and maximum output.

Lower Cost per Piece

Intelligent networking of individual work steps allows you to make maximum use of your equipment. This facilitates production at lower costs per part.

Active Occupational Health and Safety

The post-processing of 3D printed components can pose health risks due to exposure to fine dust and nanoparticles. With automation solutions, you can reduce such hazards by eliminating direct contact with hot or harmful materials.

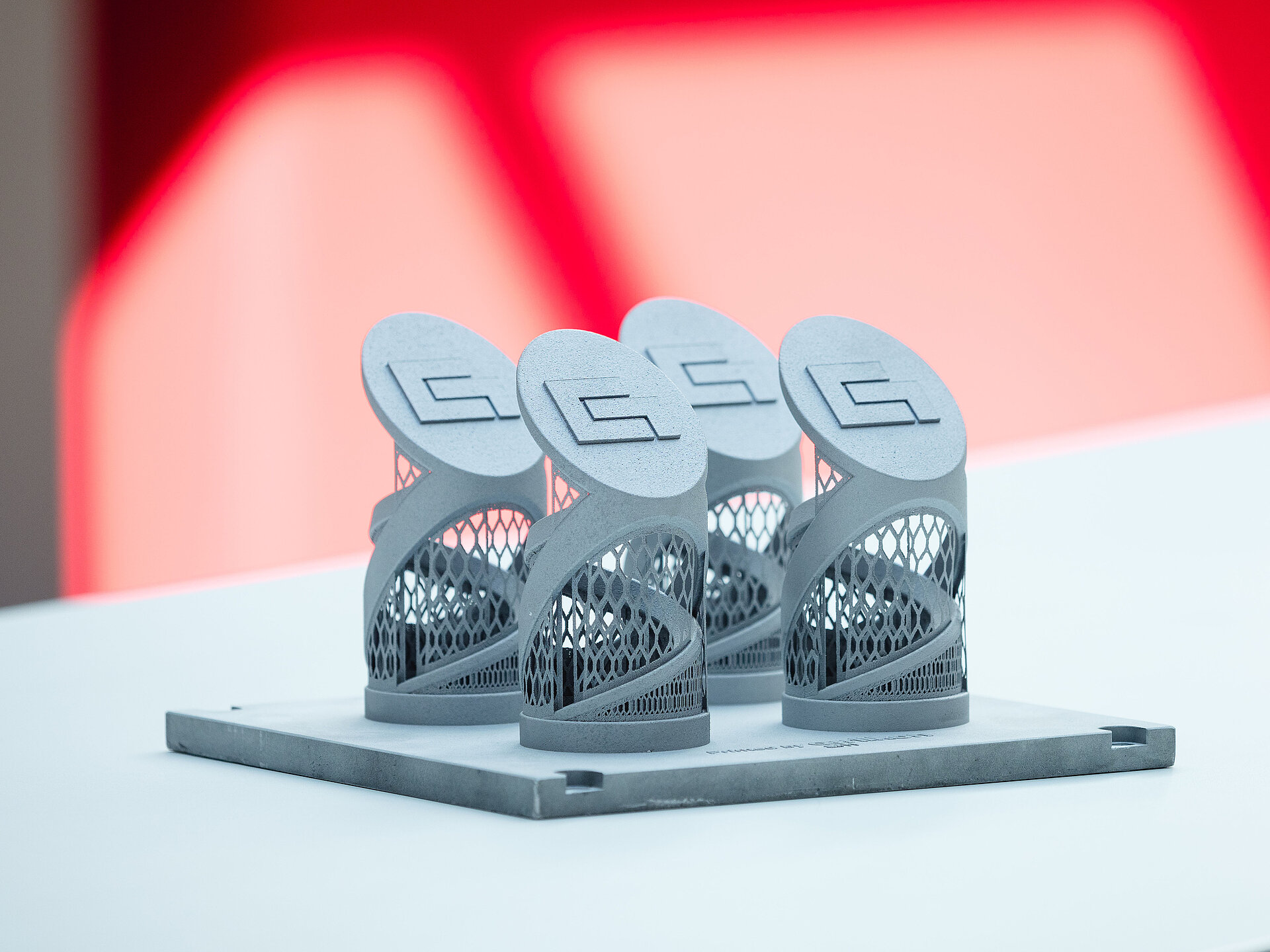

We Integrate and Interconnect the Following Process Steps for You:

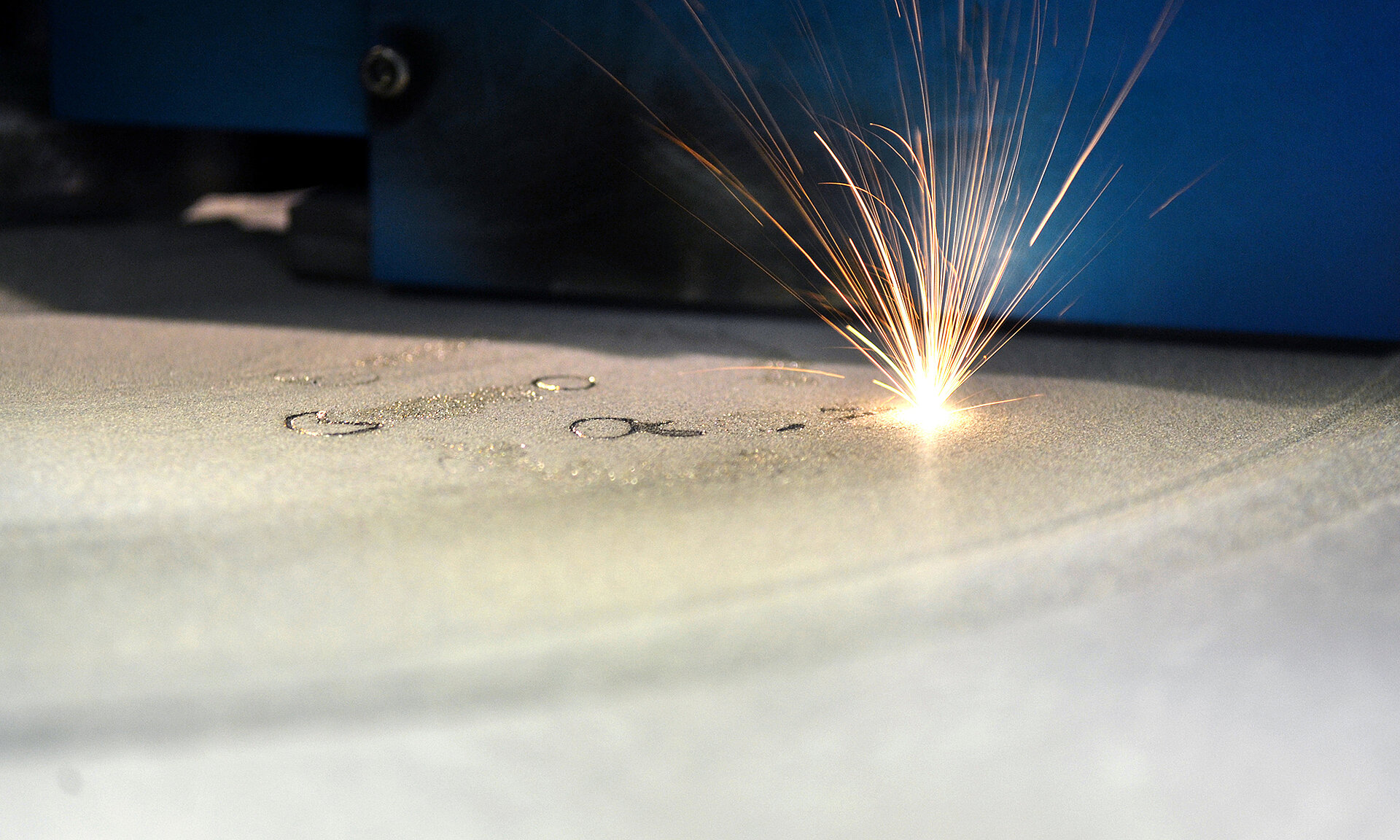

Unpacking

- Removal of build boxes and parts from 3D printers

- Depowdering

Handling

- Heat treatment

- Removal of support structures

- Separation from the building platform

Surface Treatment

- Blasting

- Polishing

- Coloring

Testing and Quality Assurance

- Component sorting

- Component geometry

- Surface quality

Automation Solutions for Additive Manufacturing Processes

Our automation solutions are aimed at both manufacturers and users of 3D printers. We focus entirely on your individual requirements in the design and develop solutions that are specifically tailored to you.

“For manufacturers and users of 3D printing equipment, we network the various working steps in additive manufacturing processes. By automating the processes, we achieve an optimal production flow and thus efficient utilization of the equipment. In addition, our solutions make working environments safer.”

Solution Portfolio

From One Source

Combine our solutions to create a holistic concept tailored to your needs. Grenzebach accompanies you from needs analysis to commissioning and beyond.

Customized Automation Solutions

We develop automation solutions that are precisely tailored to your needs by analyzing your requirements and developing a customized concept for automating your additive manufacturing. In doing so, we integrate existing machines into the optimized manufacturing process.

Our services for you:

- Consulting and needs analysis

- Simulation and software development

- Project management and training

- Installation and commissioning worldwide

- Flexible worldwide service and support

Success Storys & Case Studies

As a leading provider of automation solutions for additive manufacturing, we are constantly working on even more innovations. We present the results of research and partner projects in our Success Stories and Case Studies:

We Support You in the Automation of Your Processes

Inquire now

Your Contact Person: Oliver Elbert

What advantages do you get from automating your additive manufacturing process? We would be happy to advise you on your options. We look forward to hearing from you!

Downloads & Links

More information

About Grenzebach

Organizing complex processes intelligently and thinking ahead in automation are two of our strengths. Rely on our more than 60 years of experience in the automation of industrial processes in various industries.

Read more about our company.