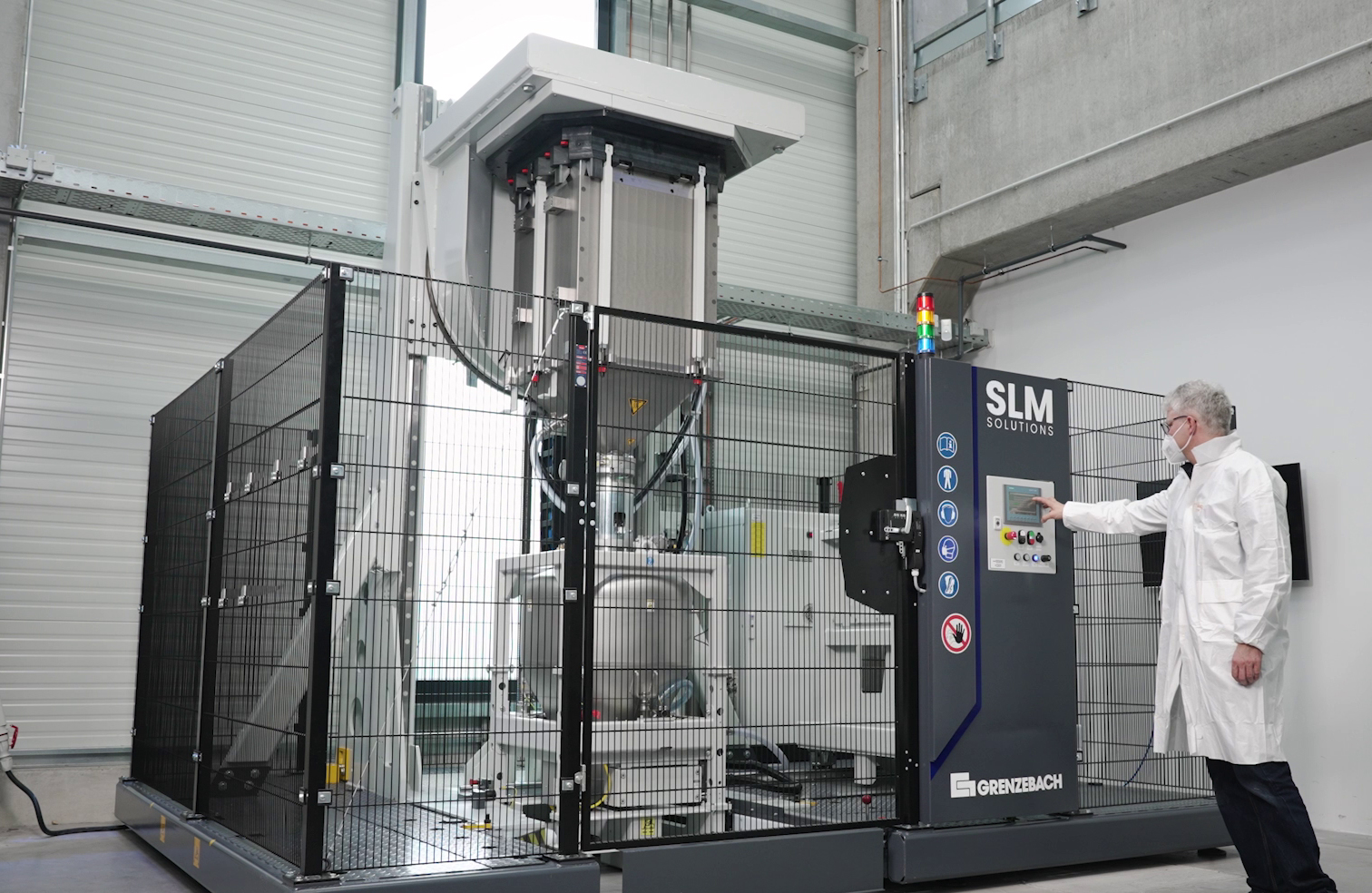

SLM Solutions and Grenzebach revolutionize the 3D printing of metal components

The project:

Our customer:

SLM Solutions Group AG headquartered in Lübeck, Germany, and with subsidiaries worldwide.

Challenges for the customer:

Engineering a depowdering solution for the company's NXG XII 600 printer that precisely and accurately handles a build cylinder weighing up to 2.3 tons while minimizing manual intervention and remaining cost-effective - with a time-to-market of less than a year.

The solution:

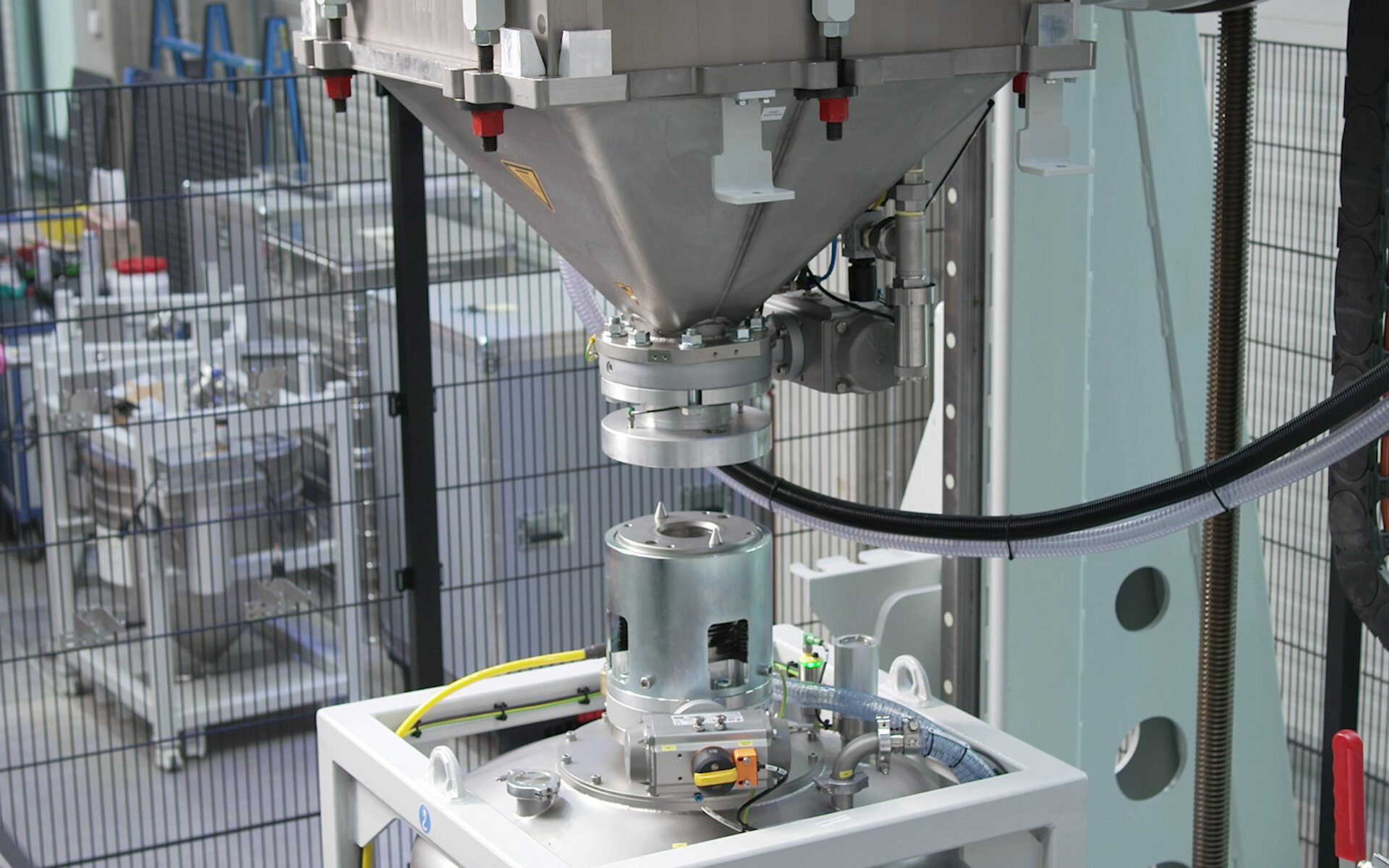

Grenzebach developed and manufactured a fully automated depowdering solution that guides operators through each process step. The system is designed so that the build cylinder can be removed entirely, and the next job can already be started while the previous one is being depowdered. The equipment also enables a seamless exchange of material without cleaning the entire solution.

Solution package in detail:

Depowdering station DPS NXG:

- for cylinders of up to 2.3 tons

- depowders over a ton of powder with gravimetric flow

- with inert gas environment, two-stage depowdering, and unpacking process

- Allows for complete reuse of the powder and building of parts on the entire substrate plate without wasting space

- Reduces downtime

Including consultation, development, prototyping, commissioning, and further development.

Benefits for our customer

Efficient utilization

due to reduction of downtimes

Versatile use

due to simple material change

Safe for employees

due to inert gas environment and automated extraction

Simple handling and integration

due to easy process steps

“We chose Grenzebach due to their many years of experience in development, automation, and handling of heavy components. We are very happy with the project and the final solution, which has already been delivered to customers all over the world. We will continue our cooperation to develop better technologies to meet the growing needs of our customers.”