Technology revolution: Grenzebach develops solution for SLM Solutions for automated depowdering of large, 3D-printed metal components

- DPS NXG allows automated depowdering of 3D components of up to 2.3 tons

- Depowdering solution can be used with several 2.3-ton printers and different materials

- SLM Solutions and Grenzebach are already planning further projects

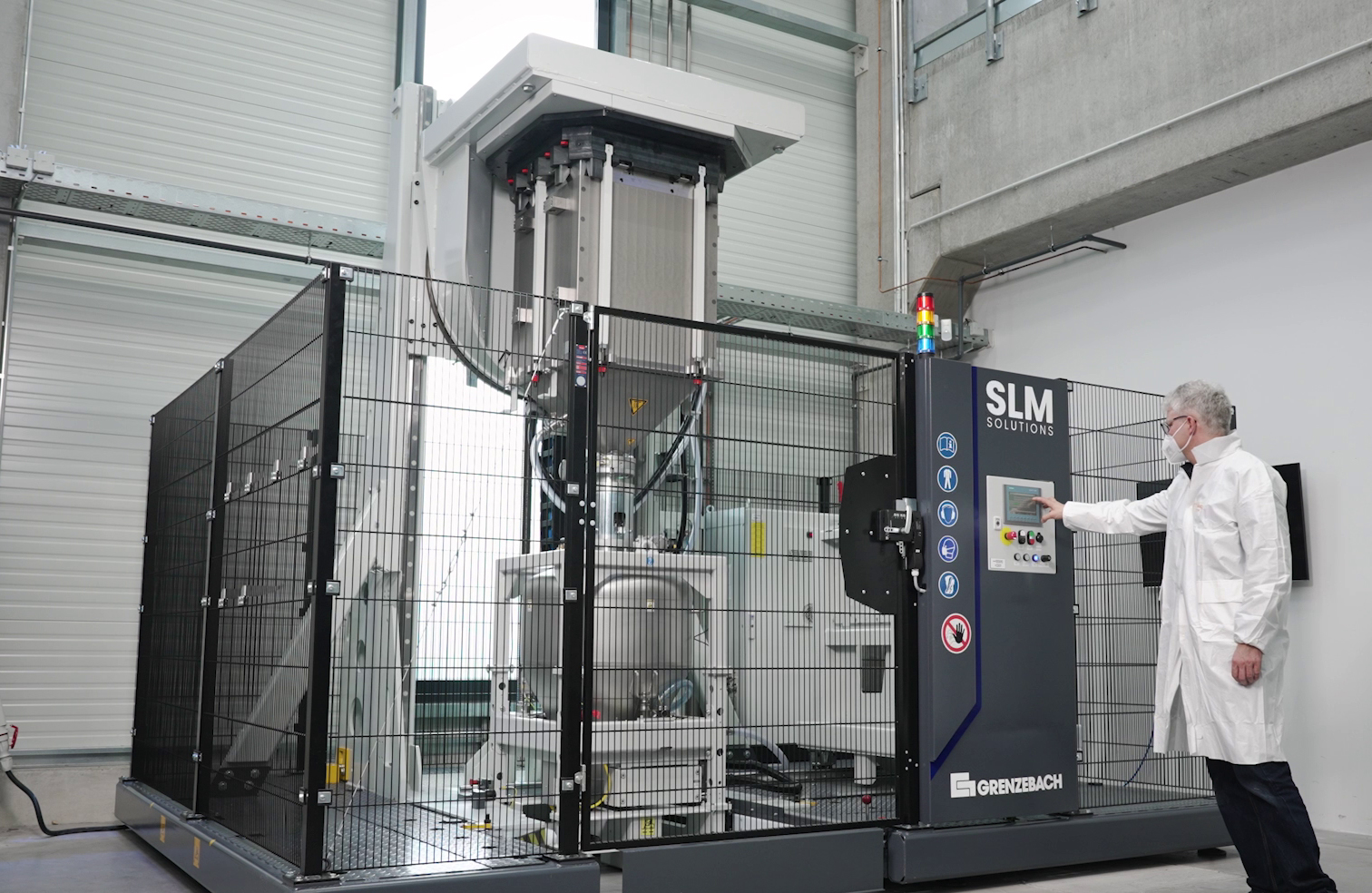

HAMLAR, LÜBECK/Germany. SLM Solutions trusts Grenzebach's expertise in developing a depowdering solution for their NXG XII 600 printer. In less than twelve months, the automation specialist has developed, designed, and manufactured a market-ready depowdering solution for SLM Solutions. The project started in March 2021. Sebastian Feist, Product Manager Factory Integration & Periphery at SLM Solutions, is happy about the project's success: "Since then, multiple production versions have been built and delivered to our NXG XII 600 customers in various countries. More than 15 systems have been ordered." The solution allows 3D printing operators to mass produce metal components on an industrial scale.

Ideal extension of the NXG XII 600 from SLM Solutions

A lot of loose powder clinging to the component must be removed in powder-based 3D metal printing after the build job. This is often still done manually. SLM Solutions was looking for a partner for its NXG XII 600 3D printer to develop an automated depowdering solution for its customers with huge components (up to 2.3 tons) that would minimize manual intervention but remain cost-efficient. Out of 17 potential suppliers, SLM Solutions finally chose the Grenzebach Group. Feist explains: "We chose Grenzebach due to their many years of experience in development, automation, and handling of heavy components."

SLM Solutions and Grenzebach developed a first concept draft together. After evaluating the concept and selecting the configuration, Grenzebach started with engineering and building the first prototype. In February 2022, Grenzebach sent the prototype to Lübeck, the German headquarters of SLM Solutions, and commissioned it. The entire project, from the inquiry to the delivery, took less than twelve months. Oliver Elbert, Head of Additive Manufacturing at Grenzebach, considers open communication to be the main factor for the success of the project.

“We at Grenzebach see ourselves as journey partners to our customers and other partners, meaning that we always stay in close contact by holding regular meetings and discussions to receive feedback on the equipment supplied and future market requirements, so that we can promptly factor this into our developments.”

Depowdering solutions for large metal components

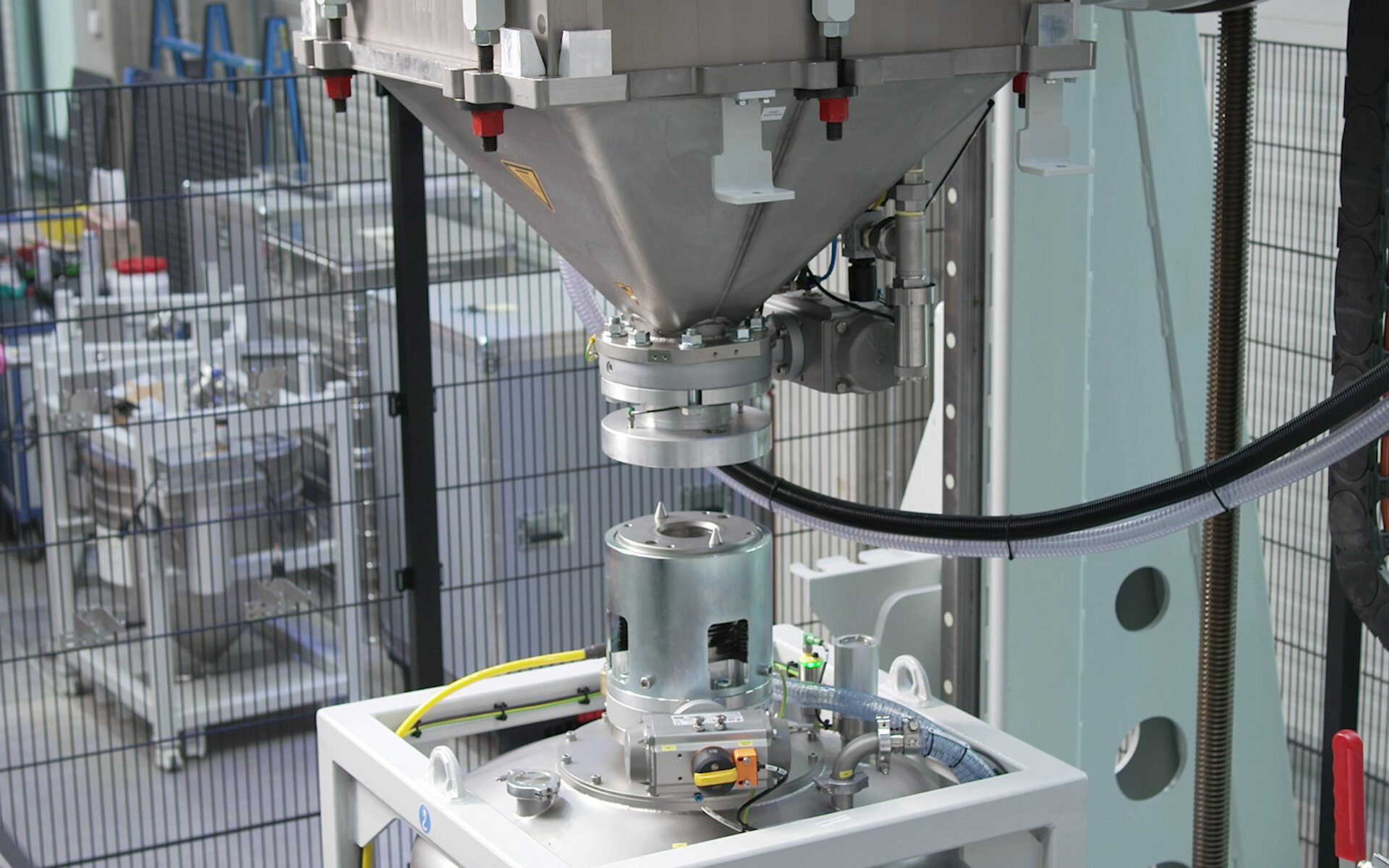

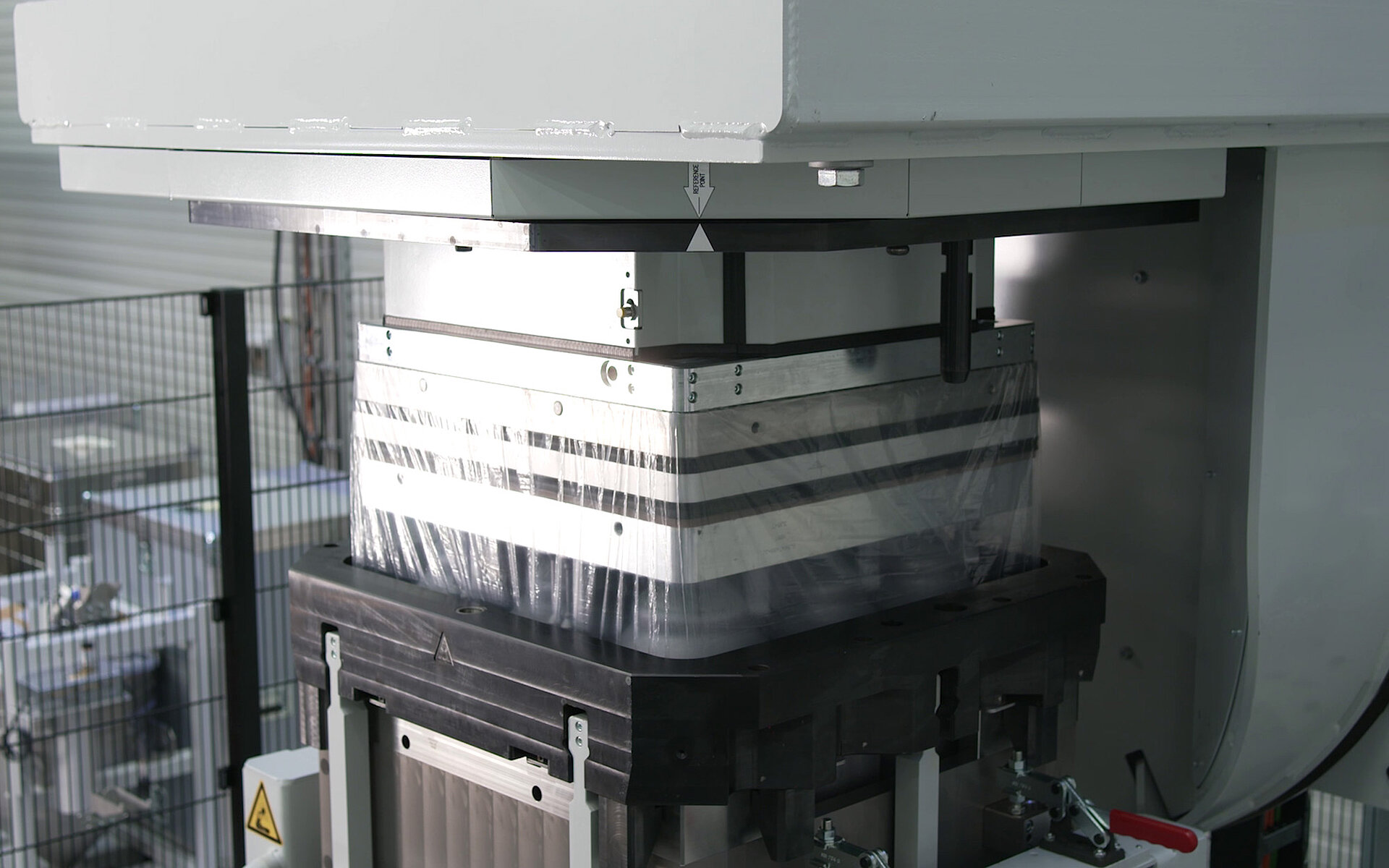

The depowdering solution is highly automated and assists plant operators throughout the entire process of depowdering and unpacking parts. Elbert explains: "The depowdering solution was developed with a focus on safety and achieving the best depowdering results." The system navigates through each process step: It starts with a fully printed SLM build cylinder, continues with the transfer of the inerted powder from the cylinder to the module tank, vibration-assisted cleaning, unpacking, and packing of the cleaned component, and ends with the cylinder ready for the following SLM process.

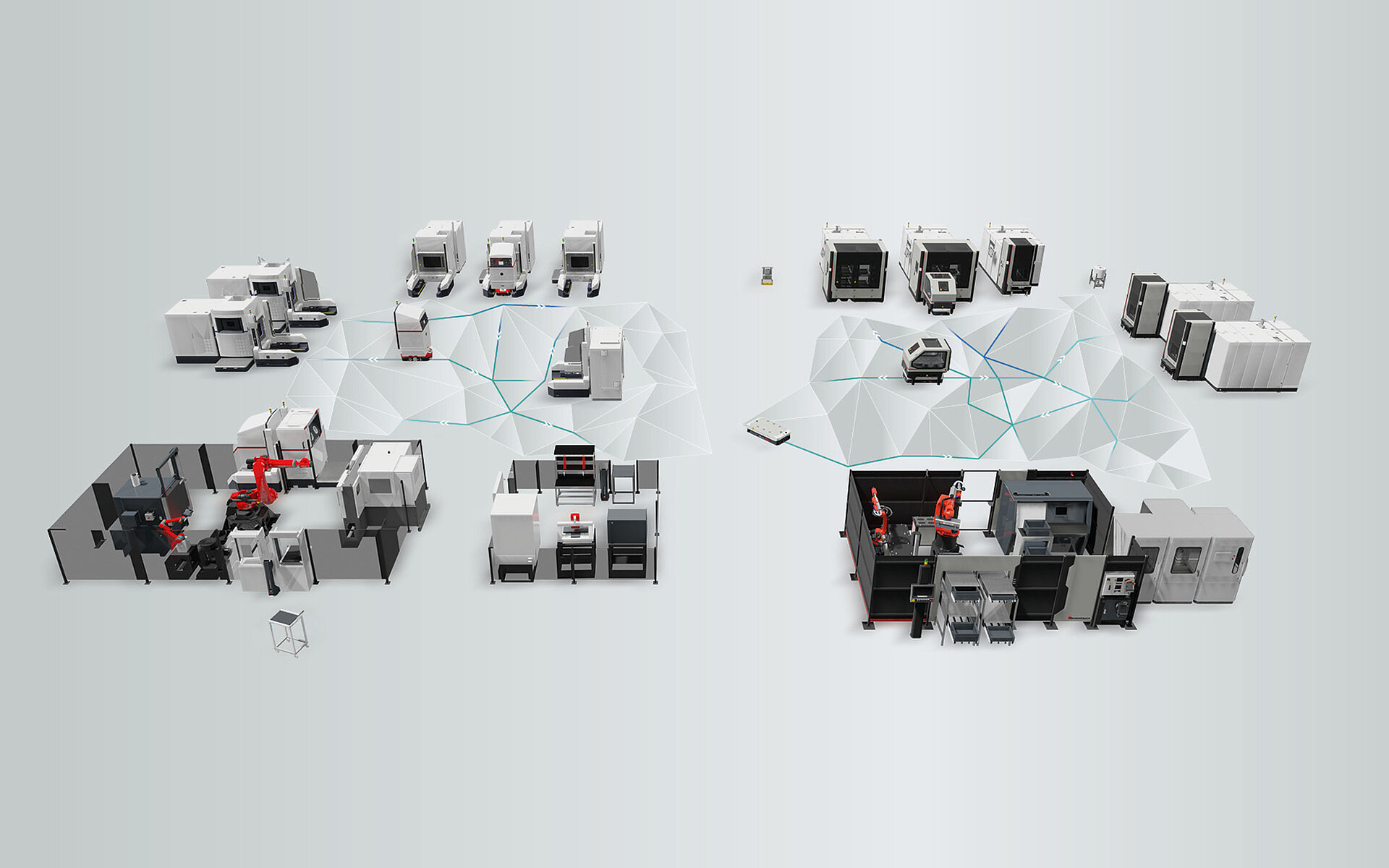

Partnership with value

Both partners experienced the cooperation as extremely rewarding. Feist says: "We will continue our cooperation with Grenzebach. We are already developing a joint, new depowdering solution for our NXG XII 600E printer. We are both striving to develop better technologies to meet the growing needs of our customers in all major industries and pave the way to series production."