Quality Non-Stop

In the production of its locally sourced BauBuche material, the Pollmeier company from Creuzberg in Thuringia, Germany attaches particular importance to very low final moisture levels and top surface quality of the veneers used. The sine-wave belt dryer supplied by Grenzebach is a key element in processing the beech veneers of which BauBuche is made. Quality non-stop, even when drying difficult veneers from high-moisture moist wood species, such as beech or poplar, which have a tendency to become wavy. With its Grenzebach system installed, Pollmeier can now be sure to have an efficient production line, from feeding to stacking of the peeled veneer.

Pollmeier's BauBuche is a local and sustainable material that has an exceptionally high strength and allows structures to be built with slimmer dimensions than products made from softwood. The laminated veneer lumber is used for building structures but also in interior design and flooring. "This is an extremely demanding product. Beech veneers tend to become wavy and also crack during drying. That is why we contacted Grenzebach. We wanted to find a solution to these problems in a joint effort," says Patrik Rodlberger, plant manager at Pollmeier Furnierwerkstoffe.

The situation: The 3.55 mm thick peeled veneer is very difficult to dry, and its handling is complex. Strength, surface roughness and susceptibility to cracking constitute a major challenge in processing this material. Some sheets easily get holes in them, which makes lifting them up with a vacuum in the feeder considerably more difficult. Moreover, most beech veneer sheets have split ends, and that also may cause problems when feeding them to the dryer.

The objective: Reliable feeding of the veneers, which have a fibre length of 2,100 mm and a fibre width of 2,200 mm, in the feeder area, trouble-free veneer transport through and smooth and proper discharge from the dryer. In addition, Pollmeier requires a very low final moisture content (< 3% abs. dry) for its BauBuche production.

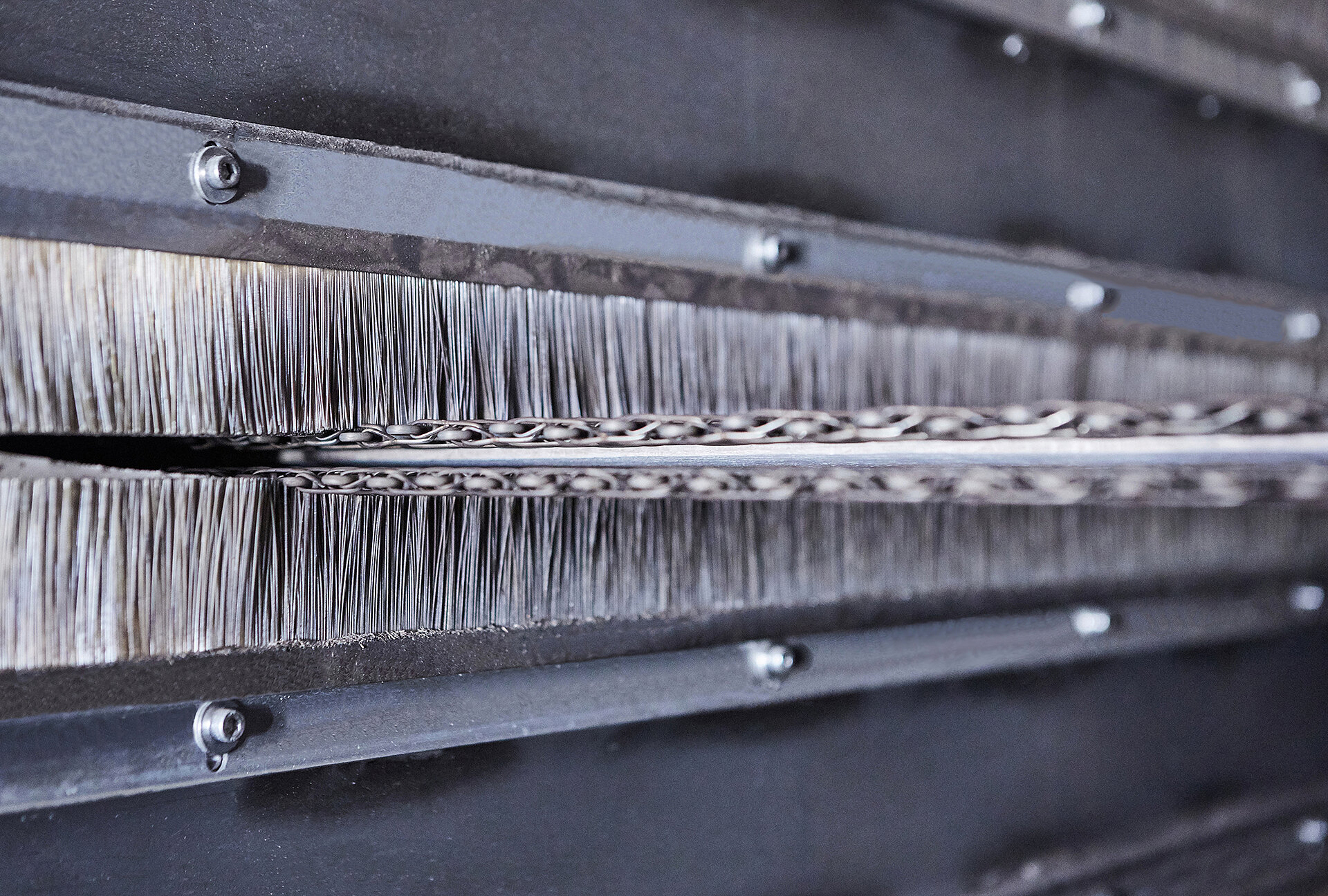

All these objectives are met with the sine-wave belt dryer Grenzebach installed at the Pollmeier plant in Thuringia. The unique sine-wave guiding system reduces the waviness of the veneers even when drying wood species with an extremely high moisture content, making handling and processing of the plywood veneers better and easier. The carry and cover belts and the special sine-wave system ensure that the moist veneer sheets, which tend to become wavy, are dried smooth and flat. Roller dryers and belt dryers without sine-wave guide systems sometimes face the problem of so-called "omega" dry veneers, i.e. deformed sheets that obstruct the run of the sheets and clog up the dryer. In the sine-wave belt dryer there are no such stoppages, and waste can be minimised. Not least thanks to the high availability of the system this also results in a better utilisation in downstream production stages.

About the drying temperatures: When the veneers enter the dryer, they have a temperature of 20-30°C, as measured on the veneer stacks at the feeder. When they exit the dryer to the transfer conveyor going to the cooling section, they have a temperature of 160-170°C. The challenge here, apart from providing an optimum air circulation, was to minimise the energy consumption of the process. "Plant efficiency matters greatly to us. That is why we have sealed the dryer infeed and outfeed so that no valuable energy is lost. This gives our customer full control over the system and the process. The customer not only saves money but also reduces emissions into the environment," explains Michael Meyer, Director Wood Technology at Grenzebach.

The smooth workflow with the sine-wave belt dryer contributes to the high quality of Pollmeier's BauBuche product. "The waviness of the beech veneer was a major challenge," adds Michael Meyer. "We have solved this issue with our innovative sine-wave system. After many trials and adjustments we have managed to achieve very good results with it. And with this system we avoid the omega problem that causes trouble and malfunctions in downstream processes.“

For Pollmeier, purchasing a sine-wave belt dryer from Grenzebach meant the end of a three-year search for a solution. "With our old dryer we experienced jams and longer production downtimes when drying beech veneer," says Patrik Rodlberger. The route to a successful solution went from Thuringia via Italy to Bad Hersfeld: Pollmeier first conducted trials with the beech veneer on a Grenzebach dryer supplied to a customer in Italy who processes poplar veneer using the sine-wave belt dryer. The trials were successful and led to the joint project. Patrik Rodlberger explains, "We have opted for Grenzebach because their team has a lot of experience in veneer drying. Grenzebach's know-how and service have assisted us with our innovation process. Of course, a number of trial runs were necessary before the optimum was reached, but then drying 3.55 mm beech veneer is not something that can easily be mastered."