Excellent! Grenzebach receives igus vector award

"The presentation of the igus vector award confirms once more our continuous efforts in developing FSW technology and plant portfolio for our customers. Our entire team is very happy about the award," says Christian Herfert, Head of Friction Stir Welding Technology at Grenzebach. The FSW process can be used to produce welds with excellent mechanical properties and high dimensional stability. In the joining process, a rotating tool uses friction and pressure to provide the necessary process heat. The material becomes malleable and the workpieces are joined at the seam in a media-tight and durable manner. Ideal for welding battery trays, heat exchangers or structural components for e-mobility. Herfert: "Thanks to the cooperation with igus and the outstanding igus products, we can efficiently exploit the strengths of FSW technology for our customers. This has enabled us to take another big step forward in the robust, safe welding of complex geometries with meander shaped welding tracks".

Energy chain from igus ensures breakthrough

Grenzebach received the award for the successful integration of an igus system into the FSW gantry machine, a top performer in the system portfolio. Alexander Feineis, Development Engineer at Grenzebach, describes the initial situation for the application: "The companion structure and media supply had to be just as flexible as the welding head of our Friction Stir Welding gantry system. The solution came from the cooperation with igus: the direct coupling of a Twister belt with a R4 energy chain, integrated in the Grenzebach energy supply unit". "The jury decided to award Grenzebach Maschinenbau GmbH the bronze vector award 2020 for this unique and creative solution," says Hans-Jürgen Alt, Managing Director of VDMA North Rhine-Westphalia, who gave the Grenzebach laudatory speech at the award ceremony.

High level, high demands on media supply

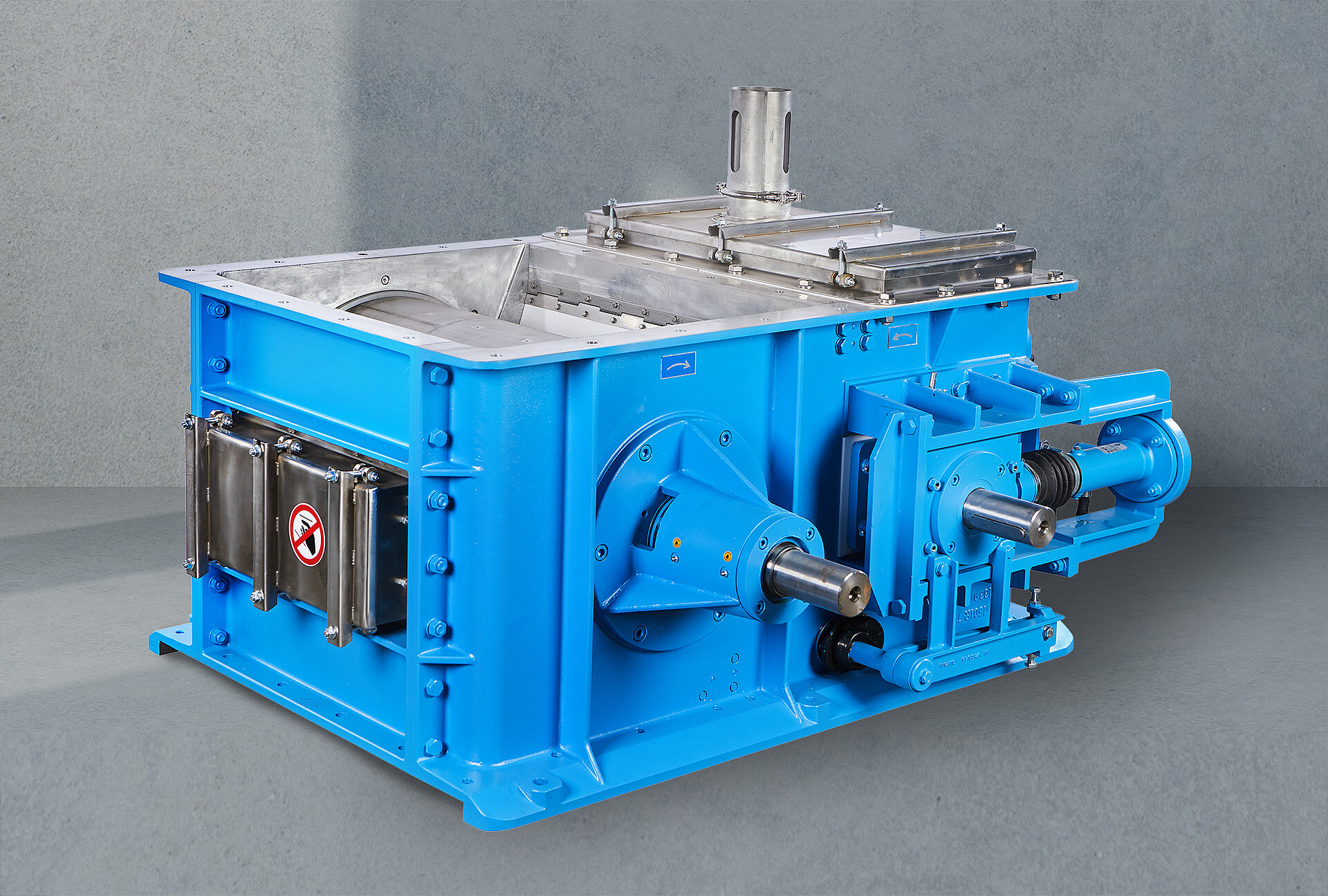

Background: To ensure a robust FSW process, it is necessary that the C-axis of the gantry system can be adjusted by up to 5°. In addition, for the safe welding of complex geometries with meander shaped welding paths - for example for heat exchangers - a rotation of the adjusted welding head of +/- 720° is necessary. As a highly complex system, the Grenzebach DynaSTIR welding head offers a sufficiently large radius of movement and the necessary degrees of freedom. For its full functionality there were a multitude of requirements for the adjacent construction as well as the media supply.

Advantages of the igus system in detail

The solution made igus possible. The pre-assembled and labeled igus system enables easy installation. Grenzebach benefits from defined interfaces and a flexible adaptation for different expansion stages and machine series. The 24/7 design of the components ensures low maintenance and low-wear operation. In case of a service call, simple and quick replacement is possible.

Award ceremony online

Grenzebach received the igus vector award in bronze, which is endowed with prize money of 1,000 euros, virtually at an online awards ceremony on Tuesday, June 23. Originally, the prize was to be presented at the Hanover Fair, which was cancelled. So the Grenzebach FSW team got the award and certificate delivered and personally presented from Michael Offner, Sales Manager Southern Germany igus at the Grenzebach's headquarters in Hamlar near Augsburg. igus GmbH presents the award every two years for innovative and creative energy chain applications.

Awarded again

For Grenzebach, the award from igus continues the distinction around the FSW process: For the real-time quality control supported by artificial intelligence (AI) during Friction Stir Welding in industrial production, Grenzebach and its software partner Weidmüller were already honored by the magazine “elektro Automation” at the beginning of 2020. Now, the Automation Award Special Prize Digitalization of the Konradin Media Group is joined by the igus vector award in bronze.