Casting parts: Grenzebach continues to invest

From June 25th to the 29th, the GIFA in Düsseldorf is all about casting parts and foundry technology, with Grenzebach right in the middle representing decision makers as well as end users from different industries. At booth F53 in hall 13, the Company will be showing a large portfolio for the casting markets of today and tomorrow. Since 2007 Grenzebach has been producing casting parts from every material preparing them to be utilized in robots and machinery. In addition, Grenzebach experts excel at mold making.

Shareholding strengthens portfolio

The internationally operating Company anticipates many opportunities within the casting markets and bought into a foundry in Nantong in the province Jiangsu in China. “With this type of engagement, we can further strengthen our casting parts portfolio, increase the availability of parts for our customers, as well as expand our expertise in producing casting parts”, says Alfred Schlosser, CEO Grenzebach China.

Jiashan: Hub for casting parts

To produce casting parts for robots and machinery, at the Jiashan location, close to Shanghai, Grenzebach built a 7,000 square meter manufacturing hall within only a few months and started operations during the anniversary year in 2018. “We have been in Shanghai for over 20 years, for 10 years we have been producing in Jiashan. For our international business, Jiashan is a major hub for casting parts and molds“, notes Thomas Liu, Director Casting Center at Grenzebach.

Parts for robots and machine tools

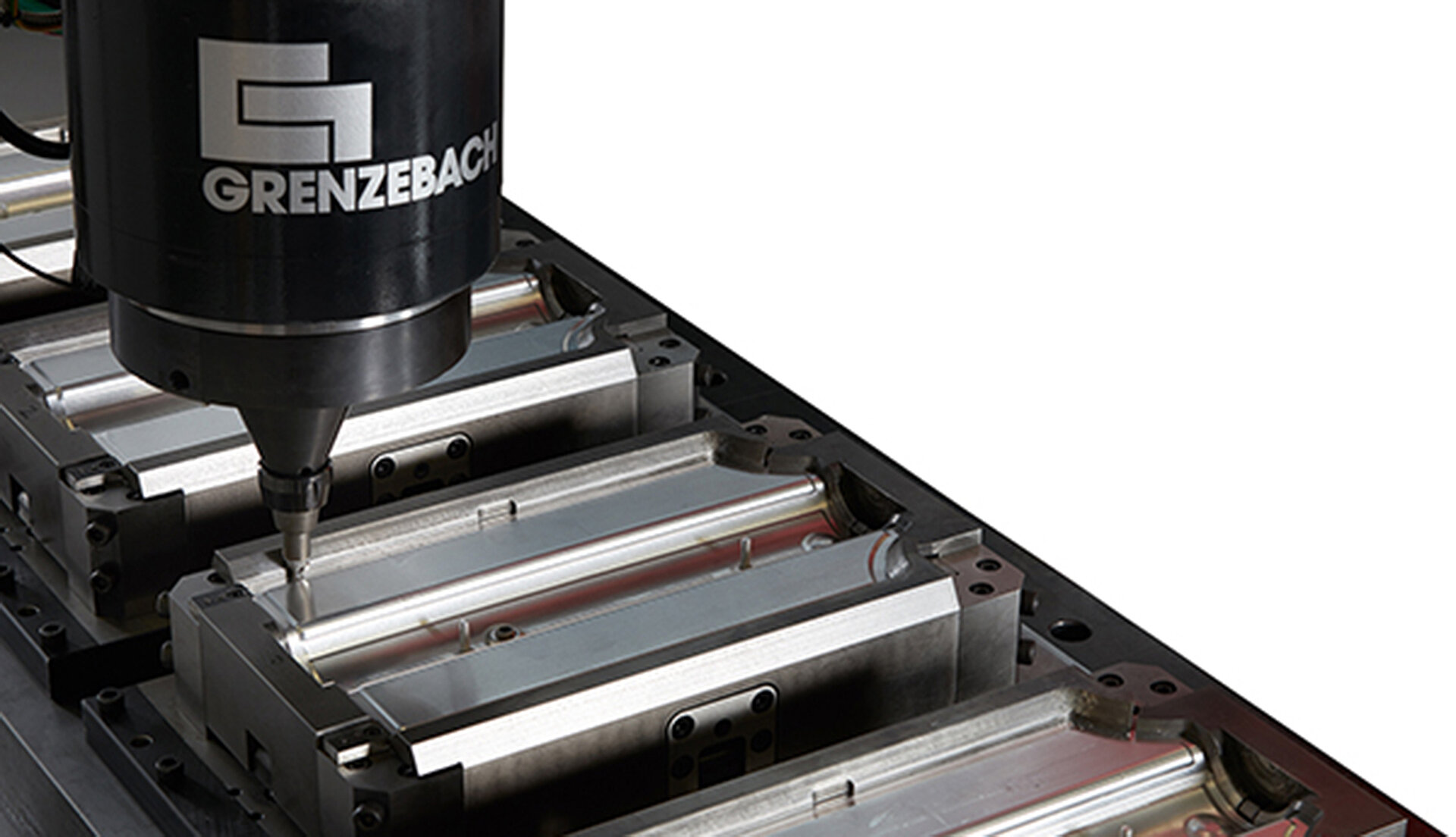

From iron to steel to aluminum casting to forged components: in Jiashan high-quality, industrial casting parts of every material are produced for the use in technical equipment and specialty machinery within the automation sector, such as industrial robots and machine tools.

For many years Grenzebach has been working with reputable customers within the automation industry, profiting from profund experiences with casting processes, production, surface treatment and quality control. With the Grenzebach Supply Chain, many different castings are available to fulfill every customer demand.

Facilitating optimized series production

Specific to customer requirements, Grenzebach designs and builds molds and models to facilitate individual and optimized series production of high-quality casting parts. Grenzebach stands for short lead times and optimum performance.

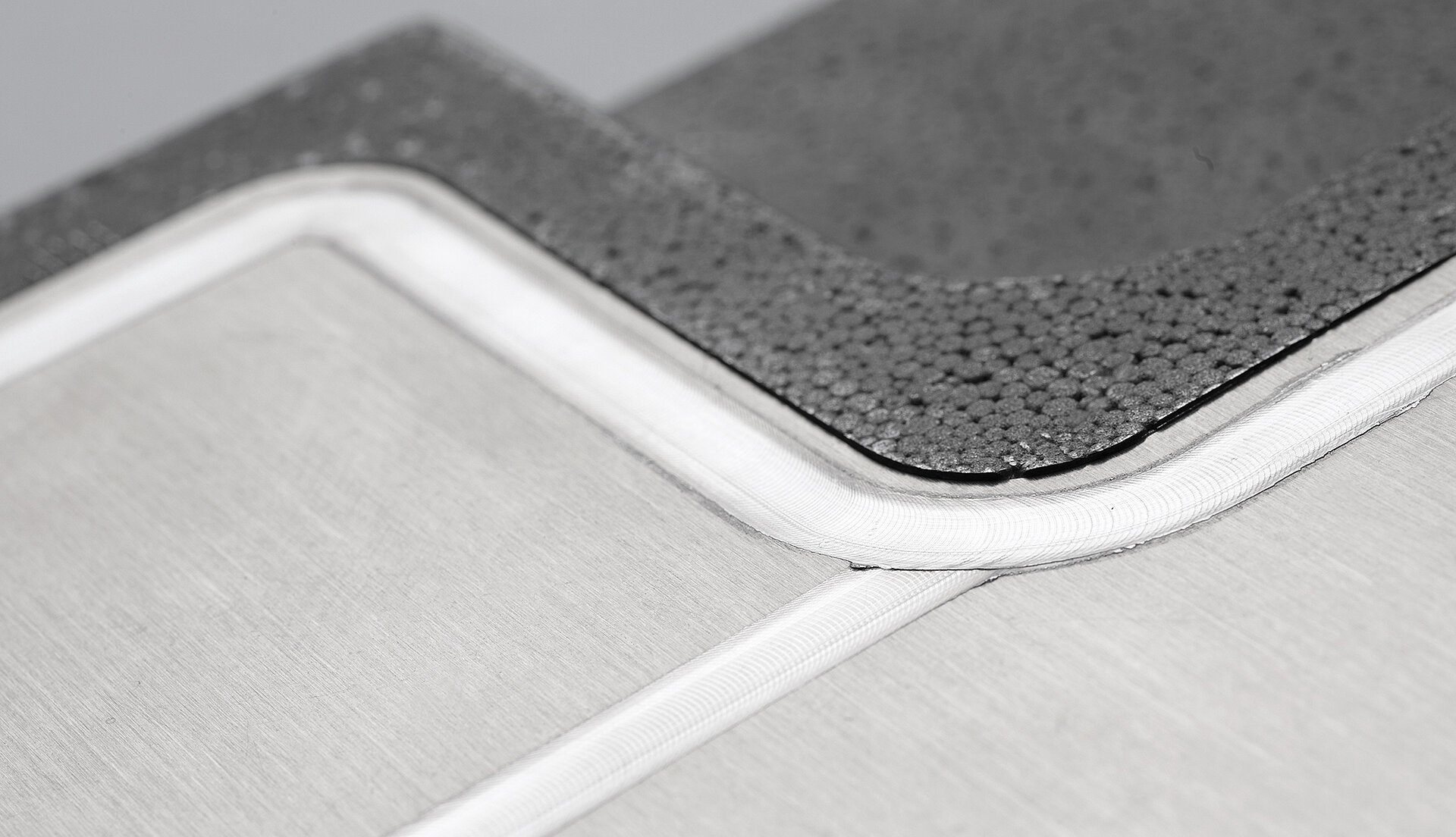

Aluminum casting material firmly bonded

At the GIFA in Düsseldorf, Grenzebach experts will also inform visitors about the friction stir welding technology, short FSW. This innovative joining technology stands for durable, solid, media and pressure-tight welding joints between workpieces. Friction stir welding does without melting, which means no pores or hot-cracking. Those are effects that lead to leaks with conventional fusion welding and become even stronger when using aluminum casting material. The FSW technology shows its strength especially when joining subcomponents of aluminium and aluminum combinations, such as casting and sheet metal material. High-quality welding joints with an outstanding surface finish are being produced. Extensive rework, such as deburring of welded seams, is eliminated.

Casting parts of highest quality will of course be showcased at the Grenzebach booth at the GIFA: Sample parts from steel, aluminum and iron – competency up close.

Also at the 17th China International Foudry Expo, a major tradeshow for casting technology for the Asian market, it was all about competencies and portfolio up close.

Casting parts of highest quality will of course be showcased at the Grenzebach booth at the GIFA: Sample parts from steel, aluminum and iron – competency up close.

Also at the 17th China International Foudry Expo, a major tradeshow for casting technology for the Asian market, it was all about competencies and portfolio up close.